|

Battery Charging and Monitoring

This page was last updated

on March 26, 2002.

|

|

One of my pet peeves in past cruises on boats

of all kinds is the lousy electrical systems--that is, the lousy capacity of

such systems. I am always annoyed to have to worry so much about running

the batteries down, sitting in near darkness, and listening to the noisy engine

clatter away while wondering if the batteries are charged yet. I was

determined to have a good house battery system on Glissando, one that

would allow normal amounts of usage over a few days without needing to run the

engine, or with a small input from solar panels or wind generator. Nothing

ruins a pleasant harbor during a cruise more than your own engine chugging away,

or someone else's.

In my research, I learned many things about

batteries, charging systems, and the electrical systems on boats in

general. I have included some sources at the bottom of this page. I realized that the batteries on most of the boats I had spent any

time on had been woefully inadequate and poorly managed by the charging

system. Why, my father's 40-footer had two battery banks with less total

power (amp-hours) than I am planning for Glissando, and much more

electrical equipment to power. I learned how poorly treated most batteries

are during charging, which explains the short life of most boat batteries, not to mention the

constant worry of running them down when anchored overnight while running a few

lights in the cabin. It seems that the basic regulators on most boats tend

to overcharge the batteries, or don't charge fast enough, or the alternators are

simply undersized or even oversized. There's a ton of information

available, and sorting through it all took quite a bit of time and energy. From all this information overload, I gleaned

that the key to successful battery management, charging and usage lies in

proper, multi-step regulation and accurate battery level monitoring--during and

after the charging sequence. Being able to note at a glance the exact

state of the batteries means that they can be charged when, and only when,

necessary, and then charged the proper amount. Of course, this equipment

is an upgrade over a more basic system, but I hope it will be worth the cost and

effort in the long run, especially during longer cruises that we plan.

(OK, so I'm having a little fun, too!)

For more information on design considerations,

charging, regulators, and the setup I am using, please check out the Ample

Power Primer, which contains some good info on these subjects and will

likely explain better than I can.

I decided upon a single house battery bank of

two Trojan T-105 golf cart batteries wired in series for 12 volts, and a single,

separate engine starting battery. This gives the house battery bank a

capacity of 220 amp-hours, which is over four times the project maximum daily burden on the

system. Read more about this on the wiring page. In practice, I think the usage will be

even less. This battery bank also allows future appliance expansion if

desired, without having to add a second or larger battery bank. We may

well install a DC refrigeration system in the future, and the planned battery

bank will allow operation of that system without need for upgrading. Please

visit the battery page for more information on the

batteries selected, their installation, and the theory behind the charging and

maintenance of batteries that makes this charging system make sense...hopefully.

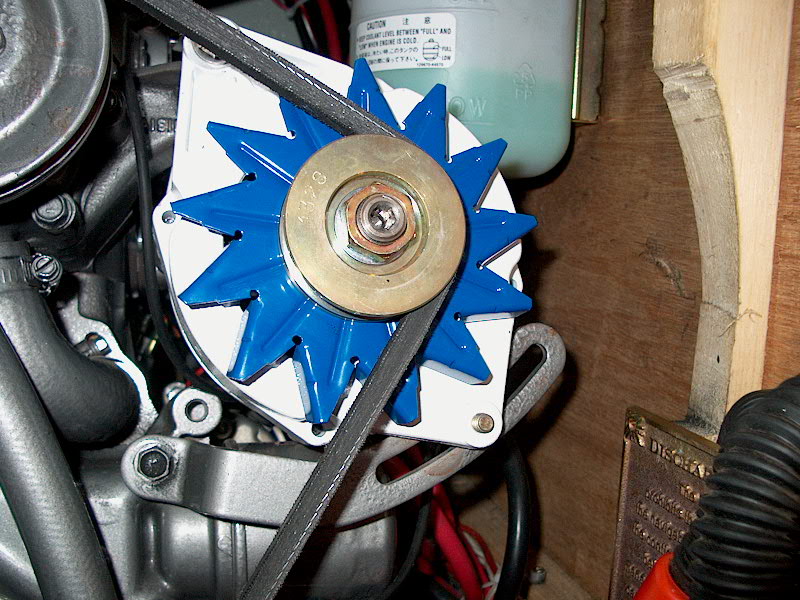

I

purchased a digital battery monitor and three-step regulator, manufactured by

Ample Technology, from Jack Rabbit

Marine. These items, in combination

with a new high output 125-amp Amptech alternator (left), will help manage the charging system efficiently

and effectively. I'll post more on the installation of these items later

when it is complete (see below for a note on the

alternator). Note that the alternator is not fully

installed--I need to modify the wood support you see to the right, to allow the

alternator to swing out more, and I also have to modify the lower bracket to

support the alternator. I

purchased a digital battery monitor and three-step regulator, manufactured by

Ample Technology, from Jack Rabbit

Marine. These items, in combination

with a new high output 125-amp Amptech alternator (left), will help manage the charging system efficiently

and effectively. I'll post more on the installation of these items later

when it is complete (see below for a note on the

alternator). Note that the alternator is not fully

installed--I need to modify the wood support you see to the right, to allow the

alternator to swing out more, and I also have to modify the lower bracket to

support the alternator.

UPDATE!

In June 2002, I replaced the alternator with a smaller one. Even with the

new engine, this monster one was way oversized, and was simply too much strain

on the engine when it was kicked in at maximum charge output. I replaced

it with a Balmar 80 amp alternator that worked very well. Click

here for details.

There are numerous connections to be made

between several components and pieces of hardware in the battery

monitoring/charging system, so the first step was to consider locations for the

various equipment. (Click here

to view a PDF schematic of the system.)

|

|

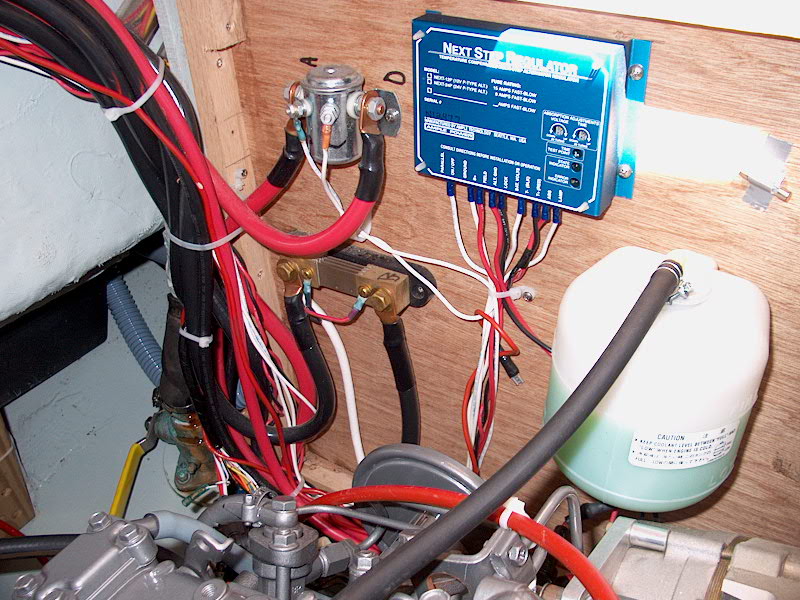

I

installed the regulator, solenoid, a heavy duty fuse block, positive and negative

distribution terminals in the engine room, trying to place them so that they

would be relatively close to the batteries' proposed location in the cockpit

locker while remaining close to the electrical panel and monitor buses.

The regulator, a shunt, and the solenoid were installed on the port side of the

engine room, while I installed the fuse block and distribution I

installed the regulator, solenoid, a heavy duty fuse block, positive and negative

distribution terminals in the engine room, trying to place them so that they

would be relatively close to the batteries' proposed location in the cockpit

locker while remaining close to the electrical panel and monitor buses.

The regulator, a shunt, and the solenoid were installed on the port side of the

engine room, while I installed the fuse block and distribution  terminals

for the positive and negative distributions on a block attached to the front of the cockpit well inside the engine room.

Other critical components include the alternator, a simple on/off battery

switch, and positive and negative distribution buses that I installed behind the electrical

panel. With these items installed, all the basic pieces are in place, and

I can measure for the connecting wires as needed. terminals

for the positive and negative distributions on a block attached to the front of the cockpit well inside the engine room.

Other critical components include the alternator, a simple on/off battery

switch, and positive and negative distribution buses that I installed behind the electrical

panel. With these items installed, all the basic pieces are in place, and

I can measure for the connecting wires as needed.

The regulator is interwired with the monitor,

alternator, and batteries with a series of wires. A solenoid is also installed

in the system, and the regulator connects the separate starting battery when the

engine is started and the alternator begins producing. When the engine is

shut down, the starting battery is automatically isolated, so there will also be

a fully charged battery available to start the engine. By sensing the charge

state, temperature, and other conditions, the regulator varies the alternator

output to the batteries for the most efficient and proper charge at all times, with

bulk charge periods, absorption charge periods, and final cut off when the

batteries reach the state of full charge. Following the supplied

schematic, I ran wires--mostly #16 AWG, but some #14AWG, as indicated--between

the regulator, monitor, alternator, distribution terminals, and batteries.

The monitor is interconnected in a similar manner to the regulator, batteries,

distributions and a few other connections as indicated on the drawing.

|

|

The other critical part of the charging system

includes heavy cables running between the batteries, distribution, engine

ground, and battery switching solenoid. Most of these cables are indicated

on the drawings as 2/0 size--heavy, stiff, expensive stuff, and miserable to

work with. After a few days' work (on and off), I finally made up the last

connection with the 2/0 cable. There are several more wiring runs that

have to be made, including the positive and negative connections to the

alternator, and the starter wiring; these final connections will be made with #2

AWG cable, which is on order as of this writing. I found Jamestown

Distributors to have the best prices on battery cable and other wiring

accessories. I am working off three or four different drawings, and it

gets a little confusing sometimes. I usually find it's best to just go for

one wire at a time, and things seem to fall into place. Actually, the

challenge is kind of fun, and I like running the wires and organizing everything

for a clean appearance. All wires are connected with ring terminals or, in

the case of the regulator connections, with fully insulated female quick

connects. Wiring to the shunt requires a shielded twisted pair, which I

purchased in a pre-made sheathed cable and connected as necessary. Wiring

for two temperature sensors, which are connected to the battery and then to the

regulator and the monitor, required twisted pairs to reduce interference.

Rather than use the expensive shielded wire I used on the shunt wiring--it was

not specifically called for like it was with the shunt wiring--I

twisted the wires together by chucking one  end of each in my drill and , with

someone holding the other ends with a pliers, slowly ran the drill to twist them

together. I taped the wires every few feet to keep then from untwisting

during installation. end of each in my drill and , with

someone holding the other ends with a pliers, slowly ran the drill to twist them

together. I taped the wires every few feet to keep then from untwisting

during installation.

7/17/01: With several months of use

behind us, I can now report on the electrical system and charging. There

have been no problems to date, although I haven't really had a chance to learn

how to use the complex monitor. I can use and view all the basic and

helpful parameters--amp-hours consumed, amp-hours remaining, percent of charge,

total amps draw at any given time, etc. However, I haven't figured out how

to set the system for optimum charging, and haven't really played with it

much. This will all come in time. One thing I need to figure out is

whether the monitor will automatically add amp-hours back in when the system is

being charged, or if I have to reset it to full every time. UPDATE--I

figured it out. The monitor DOES give this information, and is very

slick. The reason I could never figure out before whether it was offering

this information was that the system was never charging. Read on.

|

|

UPDATE!

8/13/01

A week after installing our new engine, we

headed out for a brief cruise. On the second day of the cruise, I

discovered that the batteries were very low--I couldn't start the engine without

using the emergency parallel switch. Now, I had had questions about the

charging setup since the beginning, but never really had a chance to sort it out

because I was doing so much work to the old engine. Now, it didn't seem to

be charging. Why?

After a couple moments of minor despair, and

disappointment, I was galvanized into action. I had planned to spend some

time during the cruise working on the charging system anyway, so I had with me a

printed troubleshooting guide that I found from the Ample Power website.

Reading through, I was immediately struck by one of the early paragraphs:

"When the system fails to charge,

the ignition switch is a good place to start looking. You don't need to look

at the switch itself, but you do need to see that the alternator regulator is

getting voltage when the switch is on. That is, find an input to the

alternator regulator that shows battery voltage when the ignition switch is

on, and no battery voltage when the switch is off."

I quickly realized that I had never wired the

power (on-off) terminal on the regulator, even with the old engine. The

reason I neglected this was that I wired the bulk of the electrical system in

March 2001, and had not yet installed an ignition switch or instrument

panel. Then, with the engine in a non-running condition for much of the

early part of the season, it never made its absence apparent. By August, I

had finally used enough battery power to make starting difficult--since the

batteries had never been charged all season!

I found a length of wire in my electrical kit,

and promptly wired up the regulator to the ignition switch. This

only took a few minutes. Now, when the switch turned on, there was power

to the regulator--there's a series of lights that are supposed to light, and

they did. I started the engine, and checked the regulator--the status

light was blinking a code, which, from reading the manual, I decided meant that

it was charging as designed. The energy monitor also indicated the volts

and amps that were being replaced into the house and starting batteries. Hooray!

This was a simple fix, but I admit that at the beginning, I had no idea how to

proceed. Diagnosing electrical gremlins is not necessarily my strongest

point. However, with the help of a good troubleshooting guide--and, more

importantly, the wiring diagram for the regulator--it was easy to figure out.

Of course, one thing often leads to

another! We happened to motor all the way to our next destination that

day, and when I shut down the engine, I noticed that the alarm (oil pressure and

water temperature) build into the Yanmar B-panel did not sound before I turned

the key off. Normally, this alarm sounds whenever the key switch is on and

the engine not running. But this time, I did not hear it. This

seemed strange, but it wasn't till later that I really understood that there was

a problem. Later in the afternoon, I thought I'd look into it a little

more. First, I satisfied myself that all the basics were in place--the

wiring harness was plugged in, there were no loose connections, etc. I

then decided that I had a real problem on my hands--no power to any part of the

panel, which meant no starting the engine. Why? I spent some time

looking over the system, and reading the wiring diagram for the panel and

harness in my service manual. Nothing jumped at me, and, since we were

staying put the next day, I decided to wait till the morning for a fresh

outlook.

Of course, the next morning, I immediately

noticed the fuse on the wiring diagram: a 30-amp fuse in the main power

supply to the panel. Despite my suspicions yesterday that it must be

something dumb like a blown fuse, I couldn't find a fuse on the diagram...I must

have been tired. It took me a short time to open the fuse holder and

confirm that, yes, the fuse was blown. I replaced it, and the panel and

alarm worked. I started the engine and ran it for a while, hoping to

figure out how and when the fuse had blown. When I shut down, I caught a

split second of the alarm tone before it quit--the fuse had blown again, but

this time I had isolated when it happened. For some reason, there was

additional power surging through that line at the moment the engine shut down,

which blew the fuse. I wasn't sure why, but it only started after I had

hooked up that regulator wire, so I disconnected it again for the time

being. Now I have to figure out why this is happening, and what to do to

fix the problem.

UPDATE--8/29/01

Troubleshooting the silly fuse brought to

light another, far more serious problem. After the cruise, I determined to

figure out what was causing the fuse to blow. During one session on board,

I was playing around with things a bit. One concern I had had throughout

the entire engine repower was where the spade connectors in the wiring harness

were supposed to connect to the new alternator. The Hitachi alternator

that came with the engine is internally regulated, and the terminals on the back

are different than the ones on my AmpTech alternator that is an integral part of

my electrical system. I studied the wiring diagrams and everything I could

find, and figured that the terminals were just named differently, so I connected

the wires to the field and stator terminals on my alternator. This is how

it was connected during the cruise, and there didn't seem to be any

problem--except that the charging idiot light on the panel was always lit.

Thinking that maybe I had these two wires backwards on the terminals, I switched

them. Running the engine, for some reason this did not seem right, so I

switched them back and decided, just before I was planning to head in for the

day, to run the engine with the regulator hooked up again--it had been unhooked

since the cruise. I started the engine and ran it for a couple minutes,

then shut it down--I wanted to see if that fuse was blowing on shutdown, as I

had earlier surmised. Smelling a strange smell right after shutdown, I

opened the cockpit locker to check out the battery--I didn't know if there was

maybe a problem there. There was some unusual-smelling smoke coming out of

the locker, and I couldn't identify the smell right off. It didn't really

seem electrical in nature, but what else could it be? I thought that maybe

the engine had blown a little exhaust smoke of something out of the air intake

when I shut down. Puzzled, I put the boat to bed and went home to mull

things over a bit.

The next day, I returned and tried things

again. Now wary of the previous day's smoke, I was prepared for anything

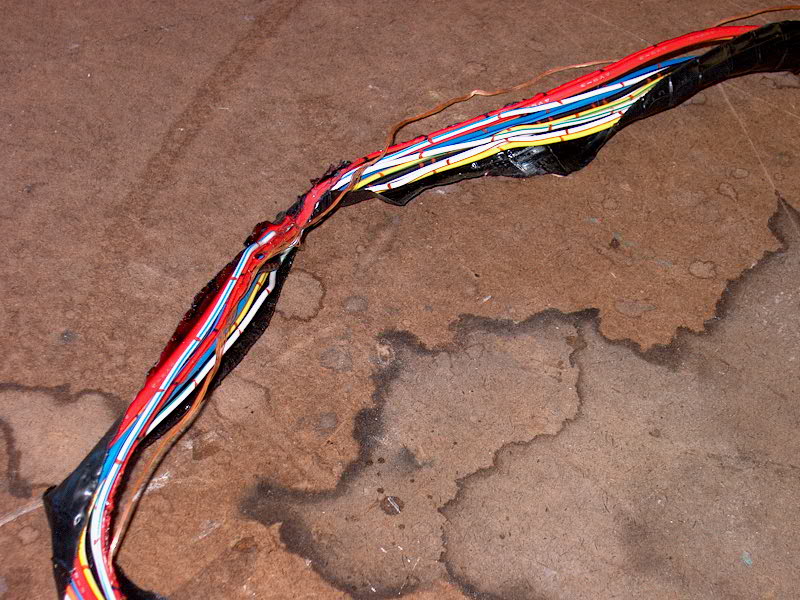

when I turned the key and started the engine. Almost immediately, the

smoke began, and I quickly traced it to the engine wiring harness extension--the

part that runs between the engine and the panel. It was smoking up a

storm, and the unusual smell was the electrical tape that the whole thing is

wrapped with--melting. Yikes! What was this?

After

shutting down the engine, I inspected the harness while it was in place.

It was toast, or at least appeared to be. I removed the harness extension

and noticed that a shorter harness, at the panel end, was also in trouble.

I removed that, and also the panel, because I could see heat damage on one of

the wires there also. I figured that my dumb switching of the wires the

day before had caused the damage--and therefore assumed that, by switching them

back, all would be well, so I drove up to Orr's Island for a new harness.

(They don't give these things away...) I described what had happened to

Bill, the owner, including the fuse problem, in the hopes that maybe he could

shed some light on what might had happened. But I couldn't get any real

answers on the alternator terminals from him, except to find out ( in general

terms) that the terminals were not the same. He was in a rush to have his

lunch. I also got the impression that he kind of thought larger

alternators and smart regulation were unnecessary and kind of stupid, so I

didn't really see getting any more beneficial assistance there. Feeling a

little chastised and defeated I left, clutching my pricey harness, and spent the

drive home trying to figure out why this might have happened. After

shutting down the engine, I inspected the harness while it was in place.

It was toast, or at least appeared to be. I removed the harness extension

and noticed that a shorter harness, at the panel end, was also in trouble.

I removed that, and also the panel, because I could see heat damage on one of

the wires there also. I figured that my dumb switching of the wires the

day before had caused the damage--and therefore assumed that, by switching them

back, all would be well, so I drove up to Orr's Island for a new harness.

(They don't give these things away...) I described what had happened to

Bill, the owner, including the fuse problem, in the hopes that maybe he could

shed some light on what might had happened. But I couldn't get any real

answers on the alternator terminals from him, except to find out ( in general

terms) that the terminals were not the same. He was in a rush to have his

lunch. I also got the impression that he kind of thought larger

alternators and smart regulation were unnecessary and kind of stupid, so I

didn't really see getting any more beneficial assistance there. Feeling a

little chastised and defeated I left, clutching my pricey harness, and spent the

drive home trying to figure out why this might have happened.

|

|

The

next day, I spent some more time inspecting the original harness and the back of

the panel. It appeared to be only one wire that had gotten hot. On

the panel, I had to spend some time replacing this wire where it was damaged,

because otherwise it might have meant that I would need a whole new panel in

order to replace this one wire, because of the widespread damage. It's a

little hard to explain why, but the wiring behind the panel is complicated, and

this particular wire split into about 100 directions, so I was legitimately

worried that it couldn't be replaced. However, I was able to figure out a

way, including replacing the little itty-bitty teeny-weenie metal connector

inside the harness plug. The

next day, I spent some more time inspecting the original harness and the back of

the panel. It appeared to be only one wire that had gotten hot. On

the panel, I had to spend some time replacing this wire where it was damaged,

because otherwise it might have meant that I would need a whole new panel in

order to replace this one wire, because of the widespread damage. It's a

little hard to explain why, but the wiring behind the panel is complicated, and

this particular wire split into about 100 directions, so I was legitimately

worried that it couldn't be replaced. However, I was able to figure out a

way, including replacing the little itty-bitty teeny-weenie metal connector

inside the harness plug.

By the way, the wire in question that was

destroyed is a small wire that, according to the wiring diagrams, is supposed to

be the hot lead for the idiot lights and such on the panel. The diagram

calls for it to run from the "exciter" terminal on the Hitachi

internally-regulated alternator back to the panel, where it splits several

ways. I started wondering exactly what function that wire had...there was

more information needed, but I knew (obviously) that something wasn't right.

I replaced the wiring harness in the boat and,

leaving the regulator unplugged for now, tried everything out. No

problems. However, I was feeling a little over my head now, so I decided

I'd better check over all the wiring in the charging system to make sure it was

wired correctly before frying another harness up. Not being an expert at

the tedious chore of troubleshooting wiring, I called upon my friend

Smitty to come have a look with me.

On the chosen day, I explained all my problems

to him, and, after a bit of time, he was able--amazingly, to me--to isolate the

issue that seemed to be causing the 30-amp fuse to blow. It seems that the

heat shrink on the terminal end of the hot lead to the panel key switch--the

wire that contained the fuse--had a small hole in it, and the metal terminal was

bearing directly on the starter hot terminal. I still don't know how he

managed to find this. It was barely noticeable. He redid this

connection, and we started the engine up--with regulator connected. He

hadn't been able to find anything wrong with the associated wiring.

We were standing in the cockpit with the

engine running, feeling smart and smug...when I noticed that strange smell

again. I knew what that meant, and flung open the cockpit locker where the

harness was run. Smoking again! I shut the engine right down, but

the damage was done--and even worse than the first time. There were long

lengths of the wire that were completely stripped of insulation, and the

associated heat had damaged the nearby wires in the harness as well.

Wonderful. So what was causing this? I was glad Smitty was

there. He immediately set to task trying to figure out what had

happened. It was the same wire as before--that little hot lead.

Obviously, way, way too much current was running through this tiny wire.

But why?

After a time, Smitty figured out the problem,

seemingly. This wire was the one that connected to the back of the

alternator, on one of the spade terminals. Obviously, these terminals are

incompatible with the ones on the original alternator. The wire was

connected to the stator terminal, and, lacking the internal regulation, it was

obviously trying to channel the full charging force of the alternator through

this wire. Also, the wire is kind of a roundabout loop--there is power

supply to the panel through the ignition switch that also feeds the hot leads

for the idiot lights and alarm. This was creating a very significant

overcurrent through the line. I think that perhaps this loop is supposed

to exist in the as-designed wiring to show that the system is properly charging;

with the external regulation and separate battery monitor, not only is this

unnecessary, but dangerous. Too bad it took two wiring harnesses to figure

this out! We determined that this wire was unnecessary, and should be

disconnected from the alternator entirely.

The harness was too fried to try the engine

again to support our new theory, so we went in. I ordered another

harness--this time online from Torresen Marine, since I couldn't face Orr's

Island again! However, a couple days later--with a fresh outlook--I

inspected the first wiring harness that I fried, and noted that it looked like

all the other wires contained therein appeared to be undamaged. I took it

out to the boat with me, intending to put it aside in storage for someday when I

would remove the burned wire--I was planning to wait for the delivery of my

second brand-new harness in another day or so, when I would install it.

However, when I got to the boat, I decided to have a go at repairing the

original harness, and spent some time removing all the old tape wrappings,

removing the offending wire and inspecting the remaining ones. They

seemed to be OK, so I reaped the harness--minus one wire--and installed it for a

test. I had already removed the terminal from the back of the alternator

and taped it up.

Success! The panel worked correctly, and

the alarm and idiot lights worked as designed when I turned the key.

Feeling bold, and thinking that we had identified and licked the problem, I

hooked up the regulator and started the engine. Everything worked

perfectly--the system charged, the harness didn't burn up, and the panel worked

correctly. I ran the engine for about a half hour, with no problems to

report. When I shut down, the fuse didn't even blow. I was so happy

that I went ahead and permanently installed the repaired harness, rather than

wait another day or so for the new one.

The large alternator charges so

fast that there are many times when we really don't need to waste engine power

driving the alternator. Therefore, I decided to install a switch that

would turn the regulator on or off as desired. Click here

to read about it.

Another reason to install the

regulator switch was because the huge alternator really put a strain on the

engine when it was charging--too much strain, as far as I was concerned.

The performance of the alternator really inhibited the engine from operating

normally. I should have known...but I had told the folks at JRM Systems

what type of engine I had, and, not really knowing any better at the time,

didn't question the alternator they sent me.

The regulator switch worked fine,

but in the end I decided it was dumb to have to throw a switch to charge

batteries. Rather than put up with a too-powerful alternator (which worked

very well otherwise), I decided to bite the bullet and replace the alternator

with a more appropriate one--a Bamar 90-75 (75 amp output).

|

|

Installation

was pretty straightforward--disconnect the batteries, unhook the wires from the

back of the existing alternator, and remove it. Then, install the new

alternator (same case size as the Amptech), hook up the wires (I had to change

three of the ends for the ground wires, since the alternator ground stud was a

larger diameter), and reconnect the batteries. Success! In addition,

the engine belt fits the new alternator pulley better...the old one was not a

perfect fit. The new alternator is perfect. The increase in power (of the

engine) over the old alternator is dramatic, so I will run the engine with the

alternator/regulator connected at all times. The switch is still there

should I need it, though. The new alternator whines more when putting out

(there's a politically-incorrect joke there somewhere), but that's OK. It

pumps out between 30 and 40 Ah of juice when the engine is running only

1200-1500 RPM, and goes up from there. Installation

was pretty straightforward--disconnect the batteries, unhook the wires from the

back of the existing alternator, and remove it. Then, install the new

alternator (same case size as the Amptech), hook up the wires (I had to change

three of the ends for the ground wires, since the alternator ground stud was a

larger diameter), and reconnect the batteries. Success! In addition,

the engine belt fits the new alternator pulley better...the old one was not a

perfect fit. The new alternator is perfect. The increase in power (of the

engine) over the old alternator is dramatic, so I will run the engine with the

alternator/regulator connected at all times. The switch is still there

should I need it, though. The new alternator whines more when putting out

(there's a politically-incorrect joke there somewhere), but that's OK. It

pumps out between 30 and 40 Ah of juice when the engine is running only

1200-1500 RPM, and goes up from there.

I'll keep the Amptech as a very

nice spare.

|

|

Electrical System Information Resources

-

Ample

Power Co.

-

Jack

Rabbit Marine

-

Powertap

-

System

E-Next Schematic

(PDF File)

-

Wiring 12 Volts for Ample Power, by

David Smead and Ruth Ishihara

-

Living on 12 Volts With Ample Power,

by David Smead and Ruth Ishihara

-

Sailboat Electrics Simplified, by

Don Casey

-

Boatowner's Illustrated Handbook of

Wiring, by Charlie Wing

-

Boatowner's Electrical and Mechanical

Manual, by Nigel Calder

|

|