|

Well, I had the insulation in hand before the

boat went in the water last spring, but just couldn't find the time to get it

installed at that point. Then, I didn't want to take time away from

sailing and more critical projects during the summer of 2001. Finally, the

time has come to install my sound insulation in the engine room!

|

|

I

purchased some high quality (read: expensive!) 1" foam/lead insulation from

Hamilton Marine. This is manufactured by Sounddown and features 1/2"

of acoustic foam on each side of a lead core, with a foil/Mylar facing on one

side. This is the good stuff; the products without lead just aren't as

effective for a given thickness. It weighs 1 pound per square foot. I

purchased some high quality (read: expensive!) 1" foam/lead insulation from

Hamilton Marine. This is manufactured by Sounddown and features 1/2"

of acoustic foam on each side of a lead core, with a foil/Mylar facing on one

side. This is the good stuff; the products without lead just aren't as

effective for a given thickness. It weighs 1 pound per square foot.

Of course, the engine room itself is now full

of stuff that is attached to the side walls--fuel filters, electrical equipment,

etc. This will make installation of the insulation more difficult,

and I haven't decided how to proceed yet. However, I did remove several

pieces of my engine box that are readily transportable, and brought them to my

shop to take care of the insulation on those parts.

A short time ago, I was digging around in my

storage room for something and moved the box that the insulation was stored

in--it's a 4x8 sheet, rolled up. Well, I got hit directly in the face

above my eye by a very surprised squirrel who had taken up residence

there! Therefore, I was hardly surprised when, a week or so later, I

removed the box and found some of the foam had been chewed up to make nesting

material. Fortunately, little of the material was damaged, and I have way

too much anyway. (I had to buy the whole roll...special order.)

Back on the boat, I had marked any

obstructions on the three pieces that I removed, so I had the outlines of

where the insulation could go marked on them. To begin, I laid out the

foam on the largest piece and cut a rectangle larger than what I needed.

Then, I could move the remains of the heavy roll out of the way and get to

work. The material is easy to cut with scissors or, my choice, a utility

knife.

Using my predetermined lines as a rough guide,

I trimmed the insulation to fit the space available on each of the three pieces

of the engine box/steps. The Mylar/foil facing is reinforced in a criss-cross

pattern, so cutting is easy by following these lines. I cut first a shallow line

through just the facing, to give me a better guide, and then two or three deeper

cuts until the material was cut all the way through. The soft lead cuts

easily.

|

|

With

the insulation cut to fit, I taped the exposed edges with foil tape. The

tape sticks well to the Mylar facing, but not so well to the exposed foam on the

bottom side (it does stick, though--it's not like it's flapping around or

anything). This seals the foam around the edges and will hopefully prevent

future deterioration and damage. I tried for the smoothest application

possible, but even my best efforts resulted in a few minor wrinkles here and

there. At the corners, I slit the tape so that I could lay the sides down. With

the insulation cut to fit, I taped the exposed edges with foil tape. The

tape sticks well to the Mylar facing, but not so well to the exposed foam on the

bottom side (it does stick, though--it's not like it's flapping around or

anything). This seals the foam around the edges and will hopefully prevent

future deterioration and damage. I tried for the smoothest application

possible, but even my best efforts resulted in a few minor wrinkles here and

there. At the corners, I slit the tape so that I could lay the sides down.

|

|

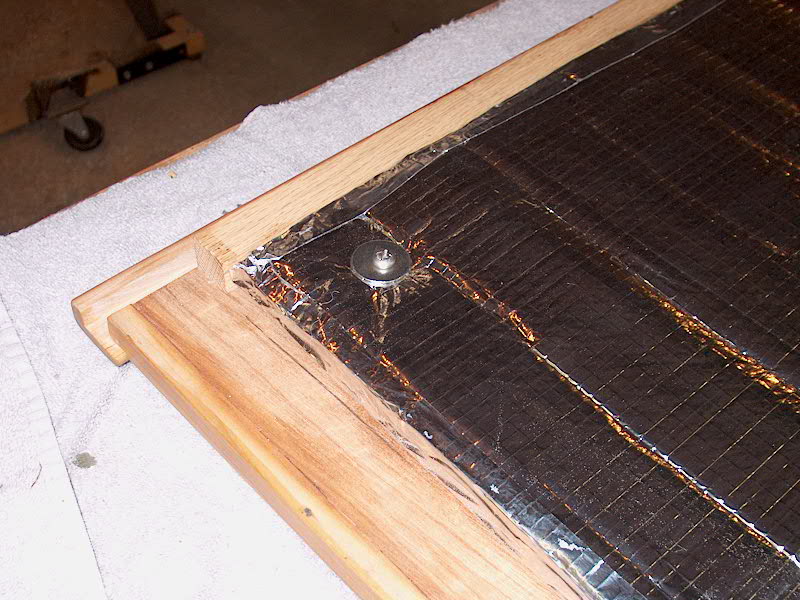

When

the insulation was taped up, I turned it over so the foam was facing up and

sprayed on a heavy coat of 3M 77 spray adhesive. Then I sprayed a similar

coat on the plywood. Carefully aligning the insulation with the markings

on the plywood, I pressed it into place, taking care not to press so hard as to

distort the lead or compress the foam. After pressing the insulation into

the adhesive all over, I further secured each piece with some #12 stainless

steel pan head screws and fender washers. I installed the screws just

tight enough to dimple the top of the Mylar facing slightly, but not to compress

the insulation. This also ensures that there's enough of the fastener

penetrating the wood to have an effective grip. The mechanical fasteners

are necessary because no adhesive will hold the heavy insulation up for any

great length of time, and, while the adhesive is important too, the fasteners

will just help hold everything tightly in place so that the adhesive is not

unduly strained--particularly on upside down pieces. I drove a number of

screws through each piece, including the middle portions. When

the insulation was taped up, I turned it over so the foam was facing up and

sprayed on a heavy coat of 3M 77 spray adhesive. Then I sprayed a similar

coat on the plywood. Carefully aligning the insulation with the markings

on the plywood, I pressed it into place, taking care not to press so hard as to

distort the lead or compress the foam. After pressing the insulation into

the adhesive all over, I further secured each piece with some #12 stainless

steel pan head screws and fender washers. I installed the screws just

tight enough to dimple the top of the Mylar facing slightly, but not to compress

the insulation. This also ensures that there's enough of the fastener

penetrating the wood to have an effective grip. The mechanical fasteners

are necessary because no adhesive will hold the heavy insulation up for any

great length of time, and, while the adhesive is important too, the fasteners

will just help hold everything tightly in place so that the adhesive is not

unduly strained--particularly on upside down pieces. I drove a number of

screws through each piece, including the middle portions.

|