|

Small Projects:

Abovedecks

This page was last updated on 1

April 2002

Chain

Pipes

Waste

and Water Deck Fills Re-lacquering

the Ports

|

|

Anchor Rode Chain

Pipes

I purchased two ABI bronze chain

pipes--one for the foredeck and one for the stern. Originally, I ordered

the two (ABI 1035 BR) from Sailnet; I received one, but not the other.

After several emails to customer service went unanswered, I called and was told

that, although a shipment had come in, mine was still on order. Grr.

A couple weeks later, I called again...but couldn't get through to an

operator. "We're experiencing unusually heavy traffic", qwoth

the voice mail. "If you like, please leave a message." I

left a message requesting that they cancel my overdue backorder and explaining

that, time and again, I try to give

Sailnet a fair chance, only to be let down each time. It's obvious

that I'm not the only one with this problem, or else their email and phone lines

wouldn't be clogged all the time. (I never received a single answer to any

of my emails. In fairness, I did receive a phone message from a

representative there later in the day, apologetic and offering me a discount

coupon at the store. Nice effort, but too little, too late.)

|

|

Anyway, rant aside, I ended up

buying another identical chain pipe at Hamilton Marine (Sailnet could learn

something from these guys...hint hint...). These chain pipes feature full

rotating covers that allow the rode and/or chain to pass through

easily. Plus, they're 3-1/2" inside diameter, so there's plenty

of room to pass a rode, thimbles, and shackles through without a problem. Anyway, rant aside, I ended up

buying another identical chain pipe at Hamilton Marine (Sailnet could learn

something from these guys...hint hint...). These chain pipes feature full

rotating covers that allow the rode and/or chain to pass through

easily. Plus, they're 3-1/2" inside diameter, so there's plenty

of room to pass a rode, thimbles, and shackles through without a problem.

On a pleasant day late in March,

it was warm enough for me to consider using epoxy, so I pulled a portion of the

cover off the bow of the boat. set up some basic staging alongside and prepared

to begin installation of the chain pipe. First, I went below and scoped

out the chain locker from the inside. I wanted to make sure I drilled the

BIG hole in the right place so that it wouldn't interfere with anything

else. To prevent damage, I unscrewed the cable clamps holding some wires

in place along the overhead; I'll reinstall these later.

|

|

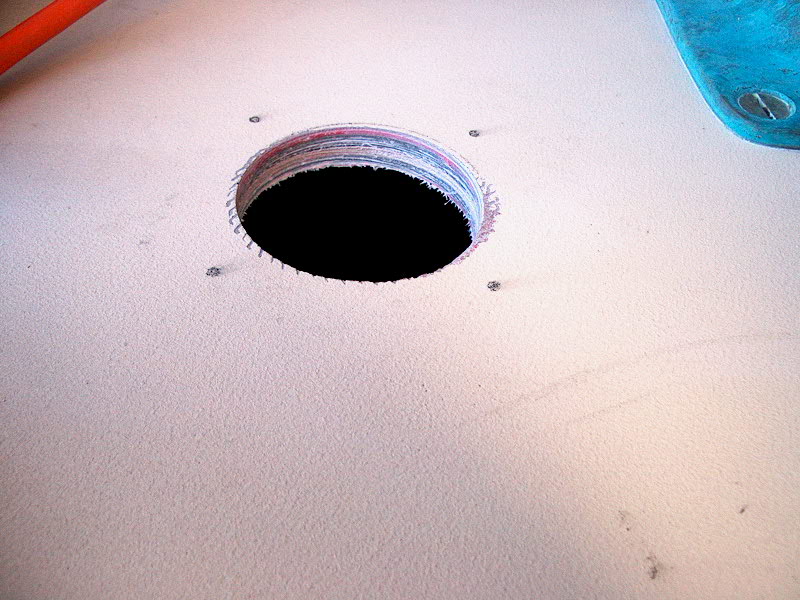

Once I had some reference points, I went back outside and prepared to drill the hole

from above. I decided to install the new chain pipe pretty much in line

with the associated anchor roller, and nearly a foot back from the end of the

anchor platform on deck. It would have been nice to keep the new chain

pipe symmetrical with the existing ventilator, but that location would have been

too close to the anchor platform and too far off the line of the anchor

roller. With this minor aesthetic consideration aside, I proceeded to

drill a 3-1/4" hole through the deck with a hole saw chucked into by big

1/2" drill. I wanted the inside hole just a bit smaller than the

actual ID of the chain pipe because I thought it would be easier to seal the

flange and keep water out. Before drilling, I double checked the

location...a mistaken 3" hole is not a fun thing. Once I had some reference points, I went back outside and prepared to drill the hole

from above. I decided to install the new chain pipe pretty much in line

with the associated anchor roller, and nearly a foot back from the end of the

anchor platform on deck. It would have been nice to keep the new chain

pipe symmetrical with the existing ventilator, but that location would have been

too close to the anchor platform and too far off the line of the anchor

roller. With this minor aesthetic consideration aside, I proceeded to

drill a 3-1/4" hole through the deck with a hole saw chucked into by big

1/2" drill. I wanted the inside hole just a bit smaller than the

actual ID of the chain pipe because I thought it would be easier to seal the

flange and keep water out. Before drilling, I double checked the

location...a mistaken 3" hole is not a fun thing.

|

|

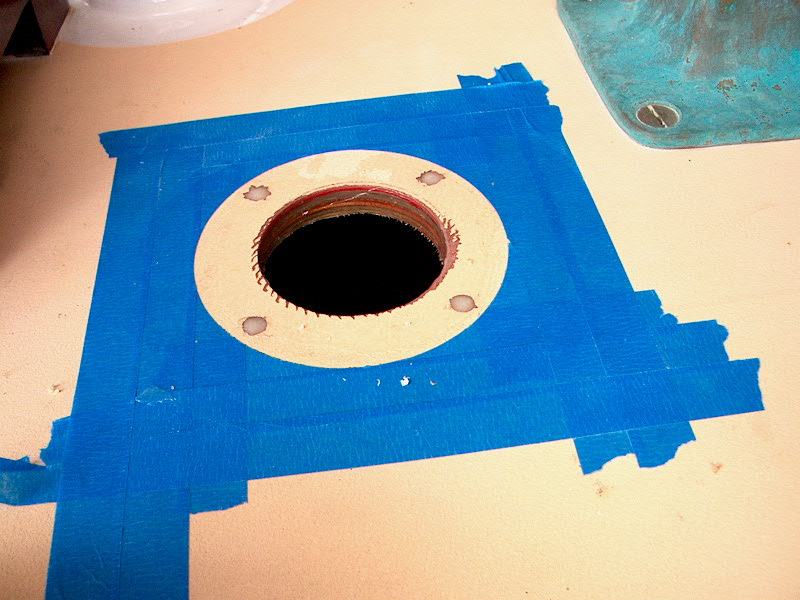

After

the hole was drilled, I positioned the deck pipe over the hole and marked for

the screw locations. I stuck masking tape all around the hole and, with a

utility knife, cut carefully around the edge of the deck pipe and removed the

tape beneath. This gives me the protection for the deck surrounding

the chain pipe to prevent epoxy or caulk from making a mess of the adjacent

deck. Then, using a 3/8" drill bit, I drilled through the top deck

skin and core and stopped once the bit reached the inner fiberglass skin; this

will prevent the thick epoxy that I'm going to fill the holes with from spilling

out below. After

the hole was drilled, I positioned the deck pipe over the hole and marked for

the screw locations. I stuck masking tape all around the hole and, with a

utility knife, cut carefully around the edge of the deck pipe and removed the

tape beneath. This gives me the protection for the deck surrounding

the chain pipe to prevent epoxy or caulk from making a mess of the adjacent

deck. Then, using a 3/8" drill bit, I drilled through the top deck

skin and core and stopped once the bit reached the inner fiberglass skin; this

will prevent the thick epoxy that I'm going to fill the holes with from spilling

out below.

|

|

I

mixed up some epoxy thickened with 406 colloidal silica and filled the drilled

holes at the screw locations, tamping it down to ensure that it was filling the

entire hole. I also covered the inside of the deck hole with the thick

epoxy; I didn't remove any of the core because my core in this area is plywood,

and removing it is not as simple as it is with soft balsa. I figure with a

layer of epoxy covering the core inside the deck pipe I should be all set.

Plus, it'll be easy to inspect over the years--just remove the cap. I

mixed up some epoxy thickened with 406 colloidal silica and filled the drilled

holes at the screw locations, tamping it down to ensure that it was filling the

entire hole. I also covered the inside of the deck hole with the thick

epoxy; I didn't remove any of the core because my core in this area is plywood,

and removing it is not as simple as it is with soft balsa. I figure with a

layer of epoxy covering the core inside the deck pipe I should be all set.

Plus, it'll be easy to inspect over the years--just remove the cap.

Later, when the epoxy is cured,

I'll redrill the epoxy plugs at the screw locations to accept some relatively

small screws that will secure the chain pipe in place. Bolts are

unnecessary, and the epoxy plugs will hold the screws and prevent any water from

ever entering the core.

|

After waiting a couple days for

the epoxy to cure, I was able to continue with the installation. A note on

the epoxy is warranted here: I used MAS epoxy resin for this, and for

another job earlier on (the "deck beam" at the chain locker

bulkhead). I don't know what the deal is, but this stuff takes

foooooorever to cure; after 48 hours or more, it is still in the green, dentable

stage. WEST System always cures hard enough to work with in only 24 hours,

sometimes less. Granted, the temperatures have been a little low for epoxy

at night, but WEST has always managed to cure faster. Plus, I always keep

the leftover pot of mixed epoxy on hand, in my heated shop, so that I can gauge

the cure time without having to trudge out to the boat; the pot inside the shop

is in the same general state of cure as the stuff on the boat. I've had the MAS on

hand for nearly a year, so I don't know if that has anything to do with it or

not (most epoxies have a more or less unlimited shelf life, though...).

Whatever the case, I don't like this stuff. WEST System has never, ever

let me down all the times I've used it, so I will purchase some more and use it

for the rest of my projects. I originally purchased the MAS a year ago because it's a lower

viscosity resin that I thought would be better for lamination (such as the false

keel project that I never got to back then). I used it now because I'm out

of WEST System. Now, I'm afraid to use the MAS anymore, for fear that it will take too

long to cure, if at all. At this point, I'm inclined to stay with a known

quantity.

|

|

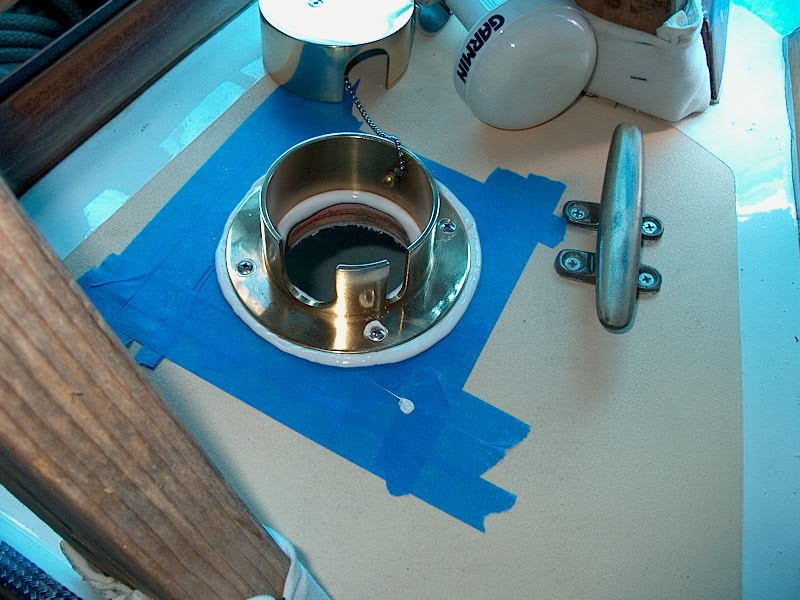

Anyway,

when the epoxy finally cured enough to continue, I drilled pilot holes with my VIX

bit--a cool bit that has an outer section that rests on the countersink of the

hardware, with a spring-loaded bit inside; when you press the drill down, it

automatically centers the pilot hole in the opening. It's great for

hardware installation. Then, I drilled small countersinks at each hole

location, to provide for that little pool of caulk around each fastener. I

applied a heavy bead of polysulfide to the deck, inside the tape ring, and

screwed the chain pipe fitting into place with four oval head #10 x 1"

screws. I left the squeezed-out caulk for cleanup once it cures for a day

or two. Anyway,

when the epoxy finally cured enough to continue, I drilled pilot holes with my VIX

bit--a cool bit that has an outer section that rests on the countersink of the

hardware, with a spring-loaded bit inside; when you press the drill down, it

automatically centers the pilot hole in the opening. It's great for

hardware installation. Then, I drilled small countersinks at each hole

location, to provide for that little pool of caulk around each fastener. I

applied a heavy bead of polysulfide to the deck, inside the tape ring, and

screwed the chain pipe fitting into place with four oval head #10 x 1"

screws. I left the squeezed-out caulk for cleanup once it cures for a day

or two.

For the stern anchor, I decided that it would be nice

to store a rode in the lazarette beneath the poop

deck. There's plenty of room outboard of the engine exhaust hose (port

side); I'll need to install a small partition inside just to keep things

separate.

|

|

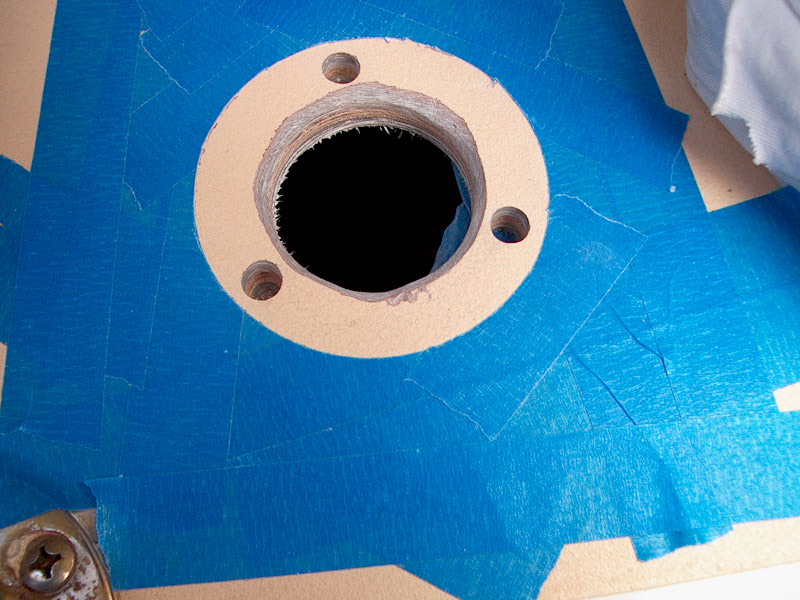

Following

the same procedure as described above for the identical fitting on the bow, I

drilled a hole for the chain pipe with a hole saw, after determining the best

location. Then, after taping, scribing, and drilling pilot holes and

countersinks, as described above, I installed the new fitting in a heavy bed of

polysulfide, leaving the spill out for clean up later when it cures. Following

the same procedure as described above for the identical fitting on the bow, I

drilled a hole for the chain pipe with a hole saw, after determining the best

location. Then, after taping, scribing, and drilling pilot holes and

countersinks, as described above, I installed the new fitting in a heavy bed of

polysulfide, leaving the spill out for clean up later when it cures.

After a couple days, the sealant

was cured sufficiently to continue. Using the edge of a multi-purpose tool

(a putty knife-like thing with some interesting shapes to the blade,

including a sort of pointed end), I carefully cut around the edges of the

fitting, separating the extra caulk from the fitting. Then, I could easily

pull the tape off, with the sealant still attached. I then had to only

clean up a little bit of residue with rags and paint thinner.

Project complete.

|

|

Waste

and Water Fill Deck Pipes

At

the same time I was working on the chain pipes, I also drilled and sealed the

holes for the new waste pipe and water tank fill. I decided to install

these on the foredeck on either side, just aft of the bow pulpit bases.

From inside the chain locker, I located where I wanted the connections to end up

and drilled a small pilot hole from inside so that I could reference it from on

deck. Then, I drilled holes for the two deck pipes with At

the same time I was working on the chain pipes, I also drilled and sealed the

holes for the new waste pipe and water tank fill. I decided to install

these on the foredeck on either side, just aft of the bow pulpit bases.

From inside the chain locker, I located where I wanted the connections to end up

and drilled a small pilot hole from inside so that I could reference it from on

deck. Then, I drilled holes for the two deck pipes with  a 1-1/2" hole

saw. The waste deck fill is a little larger, and required creating a

slight bevel at the top of the hole to allow the fitting to sit flush. I

used a small sanding drum chucked into my drill for this. With the main

holes cut, I marked for the screw locations and overdrilled the holes with a

3/8" bit for filling with epoxy. a 1-1/2" hole

saw. The waste deck fill is a little larger, and required creating a

slight bevel at the top of the hole to allow the fitting to sit flush. I

used a small sanding drum chucked into my drill for this. With the main

holes cut, I marked for the screw locations and overdrilled the holes with a

3/8" bit for filling with epoxy.

|

|

The

waste pipe is in the port side of the foredeck, which is cored with

plywood. The starboard side, however, is the original balsa core, as the

foredeck didn't require recoring on this side. At the water tank fill, I

dug out the core inside the hole for the fitting to a depth of 1/4" or

3/8". I then replaced the core with a thick epoxy mixture, and also

filled the overdrilled screw holes.

I left the two prepared holes for the epoxy to cure. The

waste pipe is in the port side of the foredeck, which is cored with

plywood. The starboard side, however, is the original balsa core, as the

foredeck didn't require recoring on this side. At the water tank fill, I

dug out the core inside the hole for the fitting to a depth of 1/4" or

3/8". I then replaced the core with a thick epoxy mixture, and also

filled the overdrilled screw holes.

I left the two prepared holes for the epoxy to cure.

|

|

After

a couple long days (see the note in the section above), the epoxy had cured

enough to continue. I prepared the screw holes by drilling pilot holes

with a VIX bit, then drilled countersinks at each location

to hold extra caulk right at the screw location where it's needed most. I

installed each fitting with three #10 x 1" oval head stainless steel

screws. I left the caulk squeeze out for clean up in a couple days after

it cures; it's much less messy that way. (Although I made a mess of

the water tank fill because I got my hand in the caulk as I was finishing up...) After

a couple long days (see the note in the section above), the epoxy had cured

enough to continue. I prepared the screw holes by drilling pilot holes

with a VIX bit, then drilled countersinks at each location

to hold extra caulk right at the screw location where it's needed most. I

installed each fitting with three #10 x 1" oval head stainless steel

screws. I left the caulk squeeze out for clean up in a couple days after

it cures; it's much less messy that way. (Although I made a mess of

the water tank fill because I got my hand in the caulk as I was finishing up...)

|

|

After

a couple days, the sealant was cured sufficiently to continue. Using the

edge of a multi-purpose tool (a putty knife-like thing with some

interesting shapes to the blade, including a sort of pointed end), I carefully

cut around the edges of the fitting, separating the extra caulk from the

fitting. Then, I could easily pull the tape off, with the sealant still

attached. I then had to only clean up a little bit of residue with rags

and paint thinner. After

a couple days, the sealant was cured sufficiently to continue. Using the

edge of a multi-purpose tool (a putty knife-like thing with some

interesting shapes to the blade, including a sort of pointed end), I carefully

cut around the edges of the fitting, separating the extra caulk from the

fitting. Then, I could easily pull the tape off, with the sealant still

attached. I then had to only clean up a little bit of residue with rags

and paint thinner.

I secured hoses to the new

fittings from inside the chain locker with hose clamps, and secured the hoses

against the bulkhead to keep them neat and out of the way.

Project complete.

|

|