|

2008 Maintenance

Log

2/9/08 | 4/14/08 |

4/19/08 | 4/27/08 |

5/26/08 | 5/28/08

2/9/08

With a snowy winter and lots of

work-related projects in

the shop, I haven't been working on Glissando, though

she's not forgotten. However, I have taken steps to

complete some of the work on the brief work list that I

posted last fall. Here is the updated list as it

stands today:

1. New anchor

rode (to replace the one broken by Wanaka

during the cruise this year). Thoughts:

Click here

2. Replace masthead light

3. Lengthen the backstay (New

Backstay on Hand:

Click

here for details)

4. Buy new chart #13305

(New Chart on Order)

5. Replace, or otherwise troubleshoot, radar

cable

6. Finally replace jibsheets with a single

length to eliminate annoying knots at cringle

7. Varnish, of course

8. I'd love to repaint the hull--probably not

this winter, but it's in the back of my mind.

9. The nonskid needs to be redone

10. A variety of sewing/canvas repair tasks

required

11. Replace lifelines

(New Lifelines on Hand:

Click here for details) |

|

|

For

the new anchor rode, I'm considering using Yale Cordage's

product called Brait. I see a lot of benefits and few

or no drawbacks when compared with normal three-strand nylon

rode, the old standby. For

the new anchor rode, I'm considering using Yale Cordage's

product called Brait. I see a lot of benefits and few

or no drawbacks when compared with normal three-strand nylon

rode, the old standby.

Here's Yale's white paper on Brait:

Anchoring Technology

As of this writing, I

haven't yet made any decisions nor purchases. |

4/14/08A

week or so ago, I broke down what remained of the snow pile

in front of the boat with my tractor bucket so that it'd

melt more quickly. Then, over the weekend I moved a

boat out of the shop, which opened up one of the shop bays,

at least for the time being. So I grabbed the

opportunity to move Glissando inside for a couple weeks so

that I could get going on varnish and other spring

maintenance.

The mast, stored on top of

the boat, just fit inside the building; I had to undo and

move the headfoil, which stuck out past the base of the

mast, but otherwise had no trouble. |

|

|

4/19/08

I spent the entire day

working on the brightwork and ports. My goal for the

day was to get all the prepwork out of the way. Last

year about this time, I stripped and refinished the

toerails, and the toerails were still in decent shape,

though with a few spots containing water damage and lifted

varnish. This was easy to scrape away, and otherwise

the toerails required only a sanding with 220 grit paper.

Some of the varnish on deck had been neglected for too long.

Last spring, I just didn't have time to address things like

the handrails, forward hatch frame, and anchor platform, and

all seasons long these neglected, cracked, paragons of

peeling varnish bothered me. So this year, I promised

myself that these areas would get the attention they needed.

In addition, it'd been a couple years since I'd varnished

the companionway trim (which remained in good condition

nonetheless since it was beneath the dodger during the

season) and the engine instrument panel surround. In

other words, all the brightwork required attention.

I scraped and sanded away

the old varnish as needed, working my way through the

sanding grits to 220 in all areas. The job made a huge

mess, of course, so afterwards I vacuumed up before

continuing. |

|

|

My normal springtime folly--the refinishing of the bronze

ports--required less work than sometimes, as last year's

finish hadn't substantially peeled away, and the bronze was

still bright in most areas. Still, I had to sand all

the ports to clean them up, particularly the two

forward-facing ports, which I'd not gotten around to last

year (these were green with verdigris). But this year

all the maintenance would get attended to: no more

slacking off. My poor boat deserved better.

Since the boat was indoors, I didn't have to immediately

worry about applying the clear lacquer to the ports, so for

now I left the ports alone so I could refocus on the

varnish. |

|

|

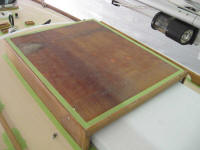

Reluctantly, I decided that the plywood top of the sea hood,

which had suffered badly over the years and had not held

varnish well, needed to become a painted surface, rather

than bright. The material had weathered where the

varnish failed during the Great Year of Neglect in 2006 (the

year I didn't launch while I built my house), and last

year's attempt to salvage the finish had only burned through

the thin mahogany veneer on the plywood. I considered

installing thin solid wood strips over the top of the sea

hood to cover the plywood, but I thought that the increase

in height--however minor (say, 1/4")--would adversely affect

the dodger's attachment points, so instead I just thought

I'd paint it with the same beige nonskid I used elsewhere.

So for now, I just taped off the top of the sea hood so I

could varnish the solid wood sides. |

|

|

With all the prepwork complete, and the boat cleaned up as

much as possible for now (the boat was still filthy after

the winter, but at least all the dirt, dust, and other

debris was gone), I masked off all the brightwork,

then applied a sealer coat of varnish to the bare wood, and

a first coat to many of the other areas, excepting (for now)

the toerail, as it was late in the day and I knew the

toerail would only require a couple maintenance coats, which

I'd begin tomorrow. |

|

|

4/27/08

Over the past week, I

applied 6 coats of varnish to all the bare wood that I

stripped, and 1-2 maintenance coats as needed to the other

wood on the boat. This wrapped up the varnish work

that I felt I needed to accomplish now, though I still had a

few removable bits--like the coamings, tiller, and

boathook--on which to apply seasonal maintenance coats,

which was underway as of this writing.

I also repainted the mast

step, and painted 2 coats of nonskid paint on the top of the

sea hood, now that I'd determined the bright finish there

could not be salvaged. |

|

|

Here's an update to the

project list that I first posted last fall:

1. New anchor

rode: Purchased and on hand (250' 1/2" Yale

Brait) |

|

|

2. Replace masthead light:

Light OK, new bulbs obtained and on hand

3. Lengthen the backstay

(New

Backstay on Hand)

4. Buy new chart #13305

(New Chart on Hand)

5. Replace, or otherwise troubleshoot, radar

cable (Pending)

6. Finally replace jibsheets with a single

length to eliminate annoying knots at cringle:

New 89' length of 7/16" sheet on hand and ready to go |

|

|

7. Varnish:

Varnish work complete for now |

|

|

8.

I'd love to repaint the hull: Not now.

Potential winter 2008 refit planned.

9. The nonskid needs to be redone:

Not now. Potential winter 2008 refit planned.

10. A variety of sewing/canvas repair tasks

required (Pending)

11. Replace lifelines:

New Lifelines on Hand and installed |

|

|

I also completed the work on the port frames. I masked

off and papered as needed, and then sprayed several coats of

exterior clear satin finish lacquer on the bronze ports.

I used the same kind I used last year, as it held up better

than any of my other attempts.

With the day's--and the

week's--work done, and with winter's grime in addition to

leftover mess from the recent work, I did a quick scrub down

to clean things up. Much better. The boat was

now ready to go back outside anytime, which would probably

happen within the week depending on other scheduled projects

due at the shop. |

|

|

5/26/08

Over the past few weeks, I

continued working on the boat sporadically as needed.

I needed the indoor space for other projects at the shop, so

a week or so after completing the varnish and other tasks I

moved the boat outdoors once more.

I didn't have a lot to do,

but some of the normal maintenance tasks I took care of

recently included:

- Painting the bottom

- Re-rigging and

prepping the mast

- Test running the

engine

- Replaced and tightened

alternator belt

- Replaced raw water

impeller

- Loaded cushions and

other gear on the boat

- Marked my new anchor

rode (using the

same system I used on the old rode)

With that, she was ready

for launching, scheduled for Wednesday, May 28. See

you then.

This photo dates to about

May 10, 2008. |

|

|

5/28/08

Launch day!

I was a bit nervous about

launching this year since it was the first time I'd be doing

it all myself with the new trailer. The day before, I loaded

the boat on the trailer and got everything ready to go,

since we (Heidi and I) planned to leave at 0500 in the

morning in order to take advantage of the high tide in

Rockland, about 45-50 minutes away.

The morning of, we arrived

at the Rockland public ramp just before 6 on a

beautiful--though windy (NW) morning. Since this was

an offshore breeze, the waters at the ramp were calm, as

expected, and fortunately everything went well with the

launching and the trailer. Once the boat was floating and

I'd done my habitual leak checks, I parked the rig in the

parking area and we prepared to bring the boat over to

Journey's End to step the mast, ostensibly for a 0930

appointment, though since we'd be there very early I hoped

to get the mast up even sooner. |

|

|

Around 0830, we got the mast stepped. It went fairly

well, though a couple members of the crew were pretty green

young kids. I ended up holding the butt of the mast in

place in the step while the others struggled with some of

the rigging attachments, particularly the headstay, since

the boat (and mast) rocked frequently in the wakes.

This distracted my attention, and it wasn't until after the

rigging was attached that I looked up and realized that the

crane had crunched my jumper struts--or the port side one,

anyway. |

|

|

|

This was a mistake that could

have been avoided, and even though Royal River, my yard from

Yarmouth, had always hooked the crane up on the forward side

of the mast--like Journey's End did this time--I knew that

it was better if they hooked up on the aft side, to prevent

clearance issues with the jumpers. Still, as much as I

care about my boat and am involved in all processes, when I

hire a subcontractor to do something, I tend to remain

fairly hands-off and let them do the job well--or not

well--on their own. I'm not one of those people to

interject suggestions or comments continually, and tend to

let others make their own mistakes, for better or

worse--it's that whole personal responsibility thing that

drives my life's value system. When I hire someone, I

just expect acceptable performance, and when they screw it

up, it's their problem. Sometimes you just can't tell

other professionals how they should go about their work, so

I let them go their own way--and suffer their own

consequences later.

Right or wrong, this is how I approach this stuff. In

this case, I wish I'd thought more about it and said

something, but since no one there seemed that concerned,

despite the obvious and (always) annoying jumper struts in

the way, I let it go, figuring they knew what they were

doing.

In the event, I have to say

that the yard handled the issue pretty well after the fact,

and within short order they had damaged strut and were

getting to work on building and painting a new one--I can't

fault how they handled the problem once it had occurred,

which gained them points. By 1130, the strut had been

replaced, with no lasting effects. While I waited for

them to build the new strut, I worked on other rigging

tasks--putting on the boom and boom vang, installing the

roller furling drum and dodger, and that sort of thing.

Once the strut was back in

business, we left the dock at the marina and headed vaguely

out. We had hoped to get the boat up to her permanent

mooring at Buck's Harbor, but despite the beauty of the day,

the wind was just all wrong--20-30 knots, and far more

northerly than we wanted for the planned course (i.e it

would have been far too close to the nose). Plus,

the boat wasn't ready to sail; ultimately, it took me

another couple hours at the rental mooring to get the sails

and rigging set up properly. So we planned to take the

boat up within the next day or two, as weather allowed.

It really was a gorgeous

day, all in all, and it was fun being on the boat. I

always feel better when she's all set up and cleaned up

after the winter, so this was a good day to get her there. |

|

|

Click

here to continue.> |

|