|

Potable Water

Systems

This page was last

updated 18 March 2003.

Galley

Water Systems

|

|

With

the countertop installed and covered in Formica, I ordered a deep sink.

The basin is 13" x 17" and is over 9" deep. When the sink

arrived, I laid out for the cutout, applied masking tape (to prevent splintering

and abrasion damage to the laminate) and cut out the hole, The sink is now

loosely in place, awaiting final plumbing before attaching it permanently with

the supplied brackets and caulk. With

the countertop installed and covered in Formica, I ordered a deep sink.

The basin is 13" x 17" and is over 9" deep. When the sink

arrived, I laid out for the cutout, applied masking tape (to prevent splintering

and abrasion damage to the laminate) and cut out the hole, The sink is now

loosely in place, awaiting final plumbing before attaching it permanently with

the supplied brackets and caulk.

At some point after the sink had

been installed, but before the boat was launched, I awoke in the middle of the

night with a thought: would the new sink, being as deep as it is, be above

the waterline of the boat? It would be close, to be sure. All I

could do was wait and find out.

Of course, the sink ended up

being too deep for its location. The bottom of the sink ended up being a

couple inches below the waterline of the boat, which, of course, means that

there was always a couple inches of water in the bowl. This was

unacceptable, of course. One reason for this is because I lowered the

countertop in the galley area by several inches when I rebuilt. This was

to provide more clear space above the countertop where it extends beneath the

cockpit bridgedeck; before, there was a scant few inches, far to tight to utilize

the space for any real storage, or even to use the space beneath the countertop

effectively since there was no real way to access it from the top.

|

|

Now I was faced with a

problem: I had to replace the sink. I was not pleased with this

development, since I was looking forward to the deep sink for washing dishes,

storing things during the day while sailing, etc. Now I had to find a sink

with the same flange dimensions, but with a bowl no deeper than 5".

This proved to be difficult! I searched low and high on the Internet and

finally found what I needed at The

Plumbing Store, with one minor exception: the flange had two holes cut

out for faucet installation. I had already installed my fresh and salt

water taps through the countertop, so this meant that the holes in the

sink flange were redundant. Oh well...for now, I'll leave it be and

address the situation more permanently in the future. I may try and

install the two taps through those flange holes, and then patch the holes in the

countertop through which they are currently installed. Now I was faced with a

problem: I had to replace the sink. I was not pleased with this

development, since I was looking forward to the deep sink for washing dishes,

storing things during the day while sailing, etc. Now I had to find a sink

with the same flange dimensions, but with a bowl no deeper than 5".

This proved to be difficult! I searched low and high on the Internet and

finally found what I needed at The

Plumbing Store, with one minor exception: the flange had two holes cut

out for faucet installation. I had already installed my fresh and salt

water taps through the countertop, so this meant that the holes in the

sink flange were redundant. Oh well...for now, I'll leave it be and

address the situation more permanently in the future. I may try and

install the two taps through those flange holes, and then patch the holes in the

countertop through which they are currently installed.

Removing the old sink was a

little bit of a trick, as the polysulfide bedding I used to secure it was

holding fast. I finally got it out, and cleaned up the countertop in

preparation for the new sink. Then, I installed the new sink in a

bed of polysulfide and weighted it down all around to hold it in place while the

adhesive cured. Then, it was a matter of reattaching my drain hose,

and the installation was complete. The new sink functions well; after a

season of use, I moved the faucets so that they came up through the holes in the

sink flange, which broadened their reach and made things function much better.

At the start of the

second season with the new sink, a new problem developed, in part because the

boat was more heavily loaded and therefore sitting lower in the water: the

sink did not drain properly. At rest, the water level in the drain hose

(equal to the level of the waterline outside) was just below the bottom of the

sink. Weight in the cockpit would cause water to flow into even the

shallower sink, and if the seacock was not closed, water would flood into the

sink when sailing on port tack. Dishwater would stagnate in the sink and

leave a disgusting residue when it finally drained overnight. Clearly, a

solution was needed.

See

the original solution to this problem here.

|

Update: 2008

After dealing with a variety of ultimately unsuitable modifications to the

galley sink setup, I decided to completely reconfigure the system, reverting to

a deep sink and locating a new sump chamber in the bilge, far removed from the

sink itself so as to address several issues with the "third try's a charm"

semi-original setup that I installed in 2003.

Read more about the newest changes in the

winter 2008

refit log. |

|

We are, for the moment at least,

keeping things simple by installing only foot manual pumps for water. In

addition, manual pumps help conserve water on board, an important consideration

with only 23 gallons in the forward tank. I installed two Whale gusher

foot pumps in the space beneath the stove, hidden behind the settee

cabinetry. There is access for future service by removing the bottom panel

of the stove enclosure, which is possible even with the stove installed. The foot pedals protrude into the

cabin for use. To

cut the slots through the cabinets for the pedals, I first cut 5/8" holes

top and bottom with a Forstner bit, then connected the holes with my jig

saw. The pumps were installed from the inside with screws through the

holes provided; access was tight because of the curvature of the hull, so I had

to use a hand screwdriver. (The horror...the horror!) One pump is

for fresh water, the other for a salt water spigot. We are, for the moment at least,

keeping things simple by installing only foot manual pumps for water. In

addition, manual pumps help conserve water on board, an important consideration

with only 23 gallons in the forward tank. I installed two Whale gusher

foot pumps in the space beneath the stove, hidden behind the settee

cabinetry. There is access for future service by removing the bottom panel

of the stove enclosure, which is possible even with the stove installed. The foot pedals protrude into the

cabin for use. To

cut the slots through the cabinets for the pedals, I first cut 5/8" holes

top and bottom with a Forstner bit, then connected the holes with my jig

saw. The pumps were installed from the inside with screws through the

holes provided; access was tight because of the curvature of the hull, so I had

to use a hand screwdriver. (The horror...the horror!) One pump is

for fresh water, the other for a salt water spigot.

|

|

Later,

I installed some of the hoses for the water system. First, I installed the

two spigots at the galley sink by drilling holes through the counter in the

proper location and inserting the faucets, which are secured from beneath with a

plastic nut. Then, I ran some hoses, beginning with the salt water

line. For this, I teed off the engine raw water intake with a bronze

3/4" tee fitting, which I inserted in the line after cutting out a section

of Later,

I installed some of the hoses for the water system. First, I installed the

two spigots at the galley sink by drilling holes through the counter in the

proper location and inserting the faucets, which are secured from beneath with a

plastic nut. Then, I ran some hoses, beginning with the salt water

line. For this, I teed off the engine raw water intake with a bronze

3/4" tee fitting, which I inserted in the line after cutting out a section

of   hose.

On one side of the tee, I installed a threaded nipple with a 3/4" -

1/2" reducer installed, so that I could install a 1/2" nipple for the

smaller water hose. Then, I ran the line to one of the pumps in the

galley, and another from the pump up to the faucet. I also ran the lines

for the fresh water pump, running them beneath the starboard settee from the

head vanity. All hoses are secured with all 316 stainless solid banded

clamps. (AWAB) hose.

On one side of the tee, I installed a threaded nipple with a 3/4" -

1/2" reducer installed, so that I could install a 1/2" nipple for the

smaller water hose. Then, I ran the line to one of the pumps in the

galley, and another from the pump up to the faucet. I also ran the lines

for the fresh water pump, running them beneath the starboard settee from the

head vanity. All hoses are secured with all 316 stainless solid banded

clamps. (AWAB)

|

|

Head

Water Systems

I also installed a

foot pump in the head, in the new vanity, using the same method described above.

I made a mistake, and placed it a little too far aft so that the seacock handle

hits the pump when I tried to close it. Oops! To fix this, I removed

the handle and bent the end 90 degrees; this enables the handle to clear the

pump body, yet still makes it easy to turn. I also installed a

foot pump in the head, in the new vanity, using the same method described above.

I made a mistake, and placed it a little too far aft so that the seacock handle

hits the pump when I tried to close it. Oops! To fix this, I removed

the handle and bent the end 90 degrees; this enables the handle to clear the

pump body, yet still makes it easy to turn.

I installed the

spigot at the head sink the same way as described above. Then, I connected

more hoses as necessary, running from the tank to a T fitting in the line, then

to the head pump and beyond to the galley pump. I cleaned the water tank,

filled it, and we were ready to go.

Rather than install

a complicated and water-hungry shower and/or electric pump, we chose to stay

simple. For a shower, we use a regular garden sprayer--the kind with a

tank that you pump up for pressure. Believe it or not, the very fine

spray from this works great as a shower, or to rinse off after a swim in salt

water--and it uses very little water. For privacy, we have a Sunshower

enclosure that we can hang from the boom.

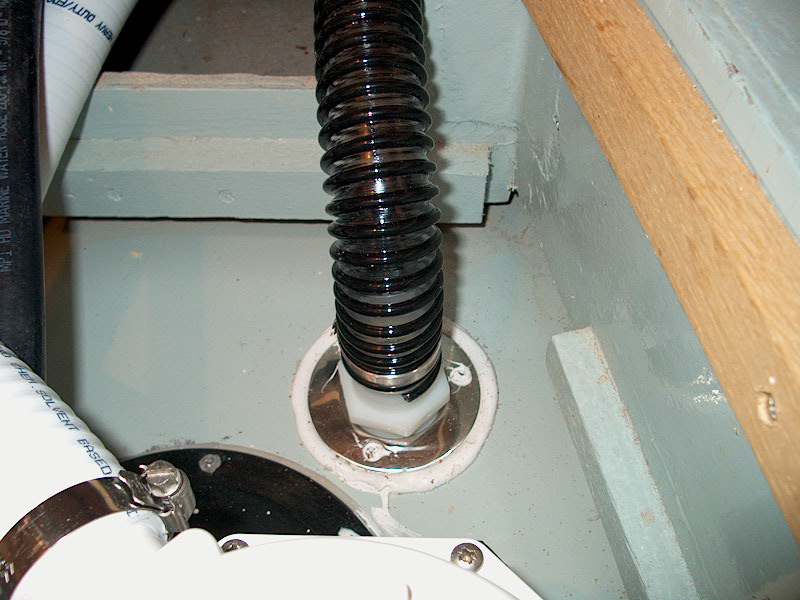

During the course of installing the

new holding tank and plumbing, I had to make a small modification to the water tank. The Triton, as

delivered, did not have a deck fill pipe for the water tank. This is

inconvenient. Last year, I filled the tank by running a hose into the

large inspection port in the tank that I installed. Less than

perfect. My sanitation plans call for a manual waste pump to be located

just forward of the holding tank, on a platform over the existing water

tank. This will make access to the tank even less convenient (though still

possible if necessary), so I thought I would take a moment and address the

issue. I discovered that the 1-1/2" PVC threaded fittings that came

with my holding tank fit perfectly into the threads of a standard waste deck

pipe. So, I drilled a hole in the tank and installed one of these in a

thick bed of 3M 101, holding it in place with screws. Later, I

installed a simple straight nipple, one end threaded (1-1/2") and the

other end barbed, and secured a length of flexible bilge pump hose to it with a

hose clamp. I ran the hose forward beneath the vee berth into the chain

locker, then up to a new deck

fitting. Voila! A new remote water

tank fill.

|

|

|

|