|

Mast Upgrades and

Maintenance

This page was last updated on 4

April 2003.

New Masthead (Anchor) Light

New

Spreader Bases | Standing

Rigging Maintenance and Inspection | New

Jumper Stays | Boom

Support Cable

|

|

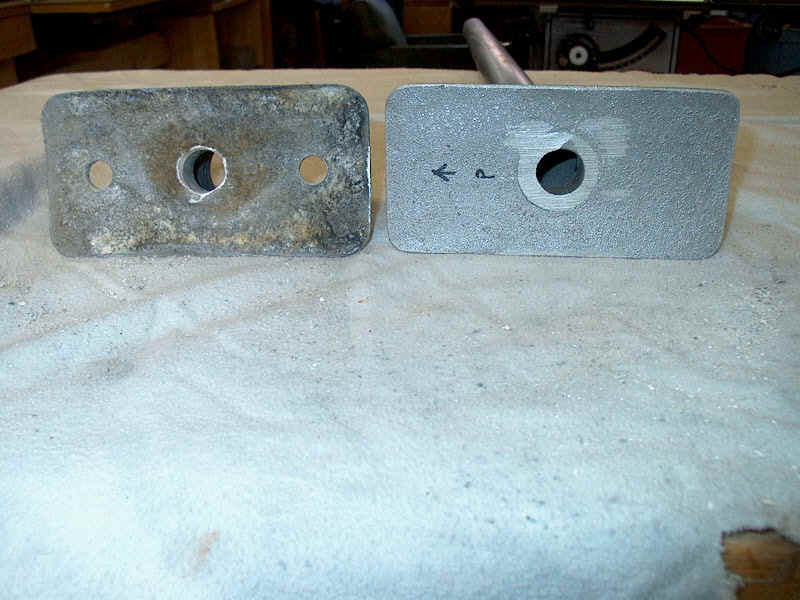

Spreader Bases Spreader Bases

I

decided to replace my original cast aluminum spreader bases after a damaging

incident during our 2002 cruise. During a raft-up with a friend's

Triton, an inconsiderate powerboat sped by at "maximum wake speed",

causing the masts on our two boats to collide several times before the wake

settled down. The impact sheared one of the spreader bases on our

friends' boat, calling into question the structural integrity of our own

spreader bases--even though they looked OK. To play it safe, I decided

that 40 years was ample service for these parts, so I ordered a new set from my

local rigger. He found a place where these castings are still a

stock item; I cannot remember the name.

The new bases are nearly

identical to the old, although the wall thickness of the spreader socket is

thicker than on the original (always a good thing). The castings came with no holes drilled, so

I'll have to take care of that. The new bases are nearly

identical to the old, although the wall thickness of the spreader socket is

thicker than on the original (always a good thing). The castings came with no holes drilled, so

I'll have to take care of that.

|

Removing the old bases

from the mast was easy, a matter of unbolting

two stainless steel bolts, which were fortunately in excellent condition.

Despite a weathered appearance on the visible parts of the old bases, they

looked generally sound at first. Once I removed them, however, it

became clear that they had been operating on borrowed time. The back

sides of the bases, where they had rested against the mast all those

years, were quite badly corroded and chalky in appearance, as one might

expect after 40 years of outdoor marine service. Nothing

particularly alarming, but deteriorated enough that I was unquestionably

happy that I had taken the time to remove them. Removing the old bases

from the mast was easy, a matter of unbolting

two stainless steel bolts, which were fortunately in excellent condition.

Despite a weathered appearance on the visible parts of the old bases, they

looked generally sound at first. Once I removed them, however, it

became clear that they had been operating on borrowed time. The back

sides of the bases, where they had rested against the mast all those

years, were quite badly corroded and chalky in appearance, as one might

expect after 40 years of outdoor marine service. Nothing

particularly alarming, but deteriorated enough that I was unquestionably

happy that I had taken the time to remove them.

Once the boat was back home in the

backyard, I brought the rigging into the shop for storage, and at that

time tried the fit of the new spreader bases with the existing spreader

tubes. The tubes didn't fit into the new sockets, though it was

close. I determined that the problem was with the roughness of the

casting, rather than a complete misfit, so I stored the stuff out of the

way for the moment with plans to bring it all out during the winter and

make the necessary adjustments.

|

When

I finally did begin work on the new bases in earnest, I found that it took

very little work with a file, first, and a small drum sander attachment in

my drill to remove the casting burrs and ream the sockets out enough for a

good fit. Once this had been done, each spreader fit home with a

satisfying clunk as it hit the bottom of the socket. I spent some

extra time cleaning up the spreader tubes, removing the rubber spreader

boots (which had been in place for two seasons), and cleaning up the

spreader tip castings. I even unscrewed the flag halyard eyes from

each spreader and reinstalled them with a good coating of waterproof

grease at each screw location, to help isolate the stainless steel screws

from the aluminum. When

I finally did begin work on the new bases in earnest, I found that it took

very little work with a file, first, and a small drum sander attachment in

my drill to remove the casting burrs and ream the sockets out enough for a

good fit. Once this had been done, each spreader fit home with a

satisfying clunk as it hit the bottom of the socket. I spent some

extra time cleaning up the spreader tubes, removing the rubber spreader

boots (which had been in place for two seasons), and cleaning up the

spreader tip castings. I even unscrewed the flag halyard eyes from

each spreader and reinstalled them with a good coating of waterproof

grease at each screw location, to help isolate the stainless steel screws

from the aluminum. |

With

the fitting work complete, I took a moment to scrape off the crusty

corrosion from the old bases and clean them up for inspection and storage

as spare parts. While doing this, I noticed a couple alarming things

about the bases that made me extra happy about installing new

replacements. First, on both parts, there were some casting

inconsistencies on the back sides, air pockets in the metal that just

didn't look encouraging. And, more seriously, on the starboard

spreader base, I noticed--upon close inspection--a hairline crack along

the top edge of the juncture between socket and base. The crack

extends over most of the top half of the socket, and is quite hard to see. With

the fitting work complete, I took a moment to scrape off the crusty

corrosion from the old bases and clean them up for inspection and storage

as spare parts. While doing this, I noticed a couple alarming things

about the bases that made me extra happy about installing new

replacements. First, on both parts, there were some casting

inconsistencies on the back sides, air pockets in the metal that just

didn't look encouraging. And, more seriously, on the starboard

spreader base, I noticed--upon close inspection--a hairline crack along

the top edge of the juncture between socket and base. The crack

extends over most of the top half of the socket, and is quite hard to see.

This is

exactly the sort of crack that leads to catastrophic failure someday if

it's not noticed, and it scared me to realize that, had it not been for

our mast-banging incident during our summer cruise that led to the failure

of our friends' spreader base, we might not have been inclined to replace

the bases, at least not unless a close routine inspection had located this

crack.

I am now aware of several Tritons that have

recently suffered spreader base failures, probably caused by similar

casting flaws like this. I guess that these relatively poor (to

begin with) castings have just about seen all the stress they can handle

after 40 or more years, and simply fail under not-abnormal strains.

Beware! |

| Later, I

carefully drilled the boltholes for securing the bases to the mast,

using the old spreader bases as a guide, and also drilled for the cotter

pin that holds the spreader tube inside the base. Creating these

holes was a matter of careful measuring, remeasuring, and measuring

again; the aluminum cut easily.

Several

weeks later, I installed the new spreader bases on the mast, bolting

them in place with the original bolts (which seemed to be in good

condition still). I applied a thin coat of waterproof grease to

the underside of the bases to help isolate them from the mast. Several

weeks later, I installed the new spreader bases on the mast, bolting

them in place with the original bolts (which seemed to be in good

condition still). I applied a thin coat of waterproof grease to

the underside of the bases to help isolate them from the mast.

|

|

Standing

Rigging Maintenance

In the fall, I removed all the

standing rigging from the mast after it was unstepped. I carefully coiled

each wire and stored them in the shop for later inspection and

maintenance. During the winter, I pulled out the wires and began some

basic maintenance. Mostly, I worked on a general wire inspection,

concentrating on the condition of the swages but also carefully inspecting the

wires for signs of damage or broken strands. I also lubricated the

turnbuckle threads with some of my new favorite waterproof grease, which I now

use all over the place. By unscrewing both ends of the turnbuckle all the

way, and then spreading a small bead of the grease on the threads and then

screwing them in all the way, I achieved a consistent, thin coating of the

grease on all the threads. Not only will this make the turnbuckles easy to

adjust and prevent them from freezing, but it will also protect the threads from

corrosion and salt spray.

|

I

use a blue waterproof multi-purpose waterproof grease on the turnbuckle

thread, as well as on many other onboard projects. The stuff I use

is leftover from years ago, when I got it from an old OMC (outboards)

dealer. I have a huge 8 oz. tube of the grease, and since a

little goes a long way, I may never need more. It's excellent

stuff, though, and I'm posting the information here so that anyone

interested can try and find a substitute that's currently available. I

use a blue waterproof multi-purpose waterproof grease on the turnbuckle

thread, as well as on many other onboard projects. The stuff I use

is leftover from years ago, when I got it from an old OMC (outboards)

dealer. I have a huge 8 oz. tube of the grease, and since a

little goes a long way, I may never need more. It's excellent

stuff, though, and I'm posting the information here so that anyone

interested can try and find a substitute that's currently available. |

|

Replacing

the Jumper Stays and Struts

I discovered that at least one of

my jumper stays had indeed been damaged when the jumpers were ruined last

August--there was a 2-3" section where the wire was abraded. I

decided to replace both wires as a precaution. Whether or not it is

financially the most efficient, I ordered Sta-Lok terminals and wire in order to

make the new stays up myself. The swaged ends are likely less expensive,

even when the rigger's labor charges are included, but I want to start shifting

to Sta-Loks in the future, and want some more practice with the terminals.

Materials ordered to replace the

jumper stays:

-

41' of 1/8" stainless

steel wire, 1x19

-

2 Sta-Lok fork terminals for

the top end, 1/8" size

-

2 Sta-Lok turnbuckle studs

for the lower ends, 1/8" size with 1/4" threads

I had

installed a Norseman terminal two years ago when I built the headstay and roller

furler, but that was my only experience with these terminals. They

really are quite easy to install, once you've done one or two. The basic

process is documented below, at least partially. The two fork terminals

arrived first (the studs were on backorder), so I installed the four ends on

different days. The photo documentary below may span both days, since some

of the pictures from the first day were out of focus or otherwise

unusable. So, in some of the photos you'll see fork terminals, and in

others you'll see stud terminals (designed to thread into turnbuckle

bodies). One

thing I noticed is that the installation procedure is slightly different between

Norseman and Sta-Lok terminals. But the basic process is the same.

Related

Link:

Sta-Lok

Installation Instructions from the Web |

|

Typical Installation

Procedure--Stalok Terminals |

First, I gathered

all the tools needed for the job:

- Cable cutters to cut the wire cleanly

- Tape, to wrap around the wire 12"

below the end

- The manufacturer's instructions

- Knife to help start the untwisting of

the wire

- Wrench for tightening the terminal

- Loc-Tite (blue) for the threads

- Polysulfide sealant

|

|

A typical Sta-Lok

fork terminal includes these parts (clockwise from left):

- The main terminal end (body)

- The wire former (goes inside the

female threads of the body)

- The socket end

- The wedge

|

|

|

A typical Sta-Lok stud

terminal includes these parts:

|

|

|

In order to ensure that

the new stays ended up the same length as the old ones, I decided to

stretch the old (existing) wire out in my garage. After I had

installed the fork terminals on the two ends of the new wire, I was

ready to cut it to length so I could install the stud terminals at the

lower ends. Since the Sta-Lok terminals are of different lengths

from the original swaged terminal ends, measuring the wire alone would

not be sufficient to preserve the overall length. So, I tied the

three forked ends (two on the new wires, one on the old) together and

secured them to my garage door, and stretched the three cables out

together. |

|

|

With the new and old

cables together, and comparing the length of the new studs versus the

old, it was easy to visualize exactly where the new cables should be cut

to length. I erred just slightly on the side of cutting the new

ones a bit shorter, since I knew that I had had the turnbuckles

tightened about halfway in the old setup--so slightly shorter (1/8"

or so only) wires would still be plenty long, but I wouldn't have to

risk bottoming the studs out if I decided to tighten the stays more than

I had previously. You can see the length difference between the

old and new terminals in this photo. |

|

|

The first step is to cut

a clean end on the wire, if one doesn't already exist. Good cable

cutters are crucial for this, though you could theoretically use a

hacksaw. The instructions call for installing some tape about 12'

down from the end, just to hold the strands in place if needed.

When the clean end is cut, slide the socked end down over the wire,

ensuring that the threads face the cut end of the wire. |

|

|

Next, begin to unlay the

outer wire strands from the inner core. A knife is helpful here to

get things started, but they unlay easily once you've gotten it

going. Untwist the outer strands down about 2-3" from the

end, exposing the central core. |

|

|

Slide the wedge over the

core, with the wider end facing the cut end. Leave about 1/8"

of the core showing above the wedge (at least for the 1/8" wire and

fittings I used for this job--check the instructions to see if this

varies). |

|

|

When the wedge is

positioned, relay the outer strands around the core and over the wedge,

ensuring that they lay in properly and evenly around the wedge.

There's a slot in the wedge, which allows it to compress over the core

later in the installation process, and you need to ensure that none of

the wire strands fall into this slot now. The wires wrapped around

the wedge makes it look like a snake that swallowed a hamster or

something. |

|

|

Slide the socket up as

far as it will go beneath the wedge, and install the former inside the

female part of the body terminal. Then, screw the end onto the

socket, using a wrench but only tightening with as much force as can be

applied with the wrench and holding the end with one hand. Then,

unscrew the end again; this allows inspection of the wire end, to make

sure that the wire strands have been properly compressed and formed

around the top of the wedge. |

|

|

This shows the wire former inside the female

part of the terminal. |

|

|

Assuming it looks right,

continue with the final assembly. Squirt some Loc-Tite thread

locker onto the male threads of the socket, and squeeze a bead of

sealant into the female end. The sealant may be polysulfide

or silicone, but if silicone is used, ensure that it is not the type

that contains acetates that can adversely affect stainless steel over

time. If the silicone is of the hardware store variety, and/or

smells vaguely like vinegar, do not use it here. It's a safer bet

to use polysulfide. |

|

|

With the sealant applied

and thread locker on the threads, screw the terminal together

again. Sealant should squeeze out the base of the socket onto the

wire when properly installed. Tighten the fitting as described

above, and wipe off any excess sealant. |

|

|

The fitting is now

installed, and retains 100% of the strength of the wire alone. It

can be unscrewed in the future for inspection, and all parts of the

terminal except the wedge can be reused on a new wire in the future.

|

|

|

The old (left) and new

studs on one of the wires. You can see that the new wire assembly

is just a tiny bit shorter than the old, as described above. |

|

Several

weeks later, I decided it was time to check the fit of my new jumper

struts and the new stays, just in case there was a problem. First,

though, I had to reinstall the main spreader bases (see above), so that

the lower jumper stay tangs would be in place. Next, I discovered

that the upper tangs (at the masthead) required a new hole for the upper

end of the stays, since the Sta-Lok fork terminals were not as deep as

the original swaged terminal ends. There was plenty of metal

there, so it was easy enough to drill the new holes a little further

down. With the new holes, and the upper tangs reinstalled at the

masthead, I secured the two new stays.

Next,

I fit the new jumpers. The rigger had left the tubes a bit

overlong to ensure that they fit perfectly, so I had to figure out how

much to cut off. Holding the various pieces in place, I determined

that about 2" needed to come off each strut, so I made the

cuts. Success! The new struts now fit perfectly. I

placed the stays in the slots at the end of each adjusting thread and

tightened the turnbuckles enough to draw things up. Everything

worked well; there was still plenty of room to tighten the turnbuckles

more, which I will do before launch day. But for now, the main

purpose had been satisfied: my new stays, and the new jumpers, all

fit and worked as they were supposed to. Next,

I fit the new jumpers. The rigger had left the tubes a bit

overlong to ensure that they fit perfectly, so I had to figure out how

much to cut off. Holding the various pieces in place, I determined

that about 2" needed to come off each strut, so I made the

cuts. Success! The new struts now fit perfectly. I

placed the stays in the slots at the end of each adjusting thread and

tightened the turnbuckles enough to draw things up. Everything

worked well; there was still plenty of room to tighten the turnbuckles

more, which I will do before launch day. But for now, the main

purpose had been satisfied: my new stays, and the new jumpers, all

fit and worked as they were supposed to.

|

|

Boom

Support Cable

I thought it would be nice to

install a boom support cable running from the backstay to the end of the boom

when at rest. I like these because they allow the boom to be

tightly and easily positioned at a proper height, both for aesthetics and to

better clear the cockpit. Having the boom tightly positioned reduced wear

and tear on its various fittings.

To

create the cable, I used a hand swager and readily-available crimping

parts. For the wire, I chose a length of 7x7 stainless steel cable.

I can't install the backstay end till the boat is in the water and rigged, but

decided to go ahead and swage a loop and shackle onto the lower end now.

Because this is a low-stress, non-critical component, hand swaging is

acceptable; it should never be used for most rigging purposes, however, as it

lacks the strength needed.

|

Typical Installation

Procedure--Hand Swaging |

|

First,

I collected the tools and parts needed. For my particular loop and

shackle, I needed a wire thimble of the proper size (5/32" cable),

a length of 5/32", 7x7 stainless steel cable, one 5/32" crimp

fitting, and the hand swaging tool.

The hand swager couldn't be

simpler: you install the two bolts on either side of the proper

hole in the tool (it accepts four different size fittings), install the

crimp fitting inside, properly positioned so that the swage will be

close to one end (you do 2 or more crimps for each terminal), and simply

tighten the bolts evenly to pull the two halves of the tool together,

pressing the fitting tightly onto the wire. |

|

|

With

the fitting positioned in the tool and light pressure on the bolts to

hold it, I ran the cable through one side of the fitting. I

slipped a thimble over the end of the shackle I was using, and ran the

wire through the eye and over the thimble, then back through the other

side of the swage fitting inside the tool. |

|

|

Leaving

a small amount of the cable protruding through the fitting, I tightened

the slack out of the other side of the cable, carefully positioning the

thimble and wire as I did so. Once the slack was out, and things

properly positioned, I held things in place and started cranking down

the bolts on the tool. |

|

|

Ensuring

that the cables didn't pull our or fall off the thimble, I tightened the

two bolts evenly until the swage was complete. Then, I backed off

the bolts, repositioned the fitting inside the tool, and repeated the

process, creating a second swaged area on the fitting. Depending

on the length of the fitting, you should have 2, 3, or 4 crimps on each

fitting. The small size of this one prohibited more than two

crimps. |

|

|

This

is the finished product. |

|

Once the boat is rigged, I'll

complete the installation of the boom support cable by clamping the other end of

this cable to the backstay at the appropriate height. More to come.

|

|

Davis

Megalight (Anchor Light)

Being stupidly and

unnecessarily power-miserly, I never enjoyed leaving the old anchor light on

all night long. It just caused me stress and poor sleep. Dumb, I

know--but sometimes one just has a mental block that one can't get by.

I hoped for a better solution.

I found it in the Davis

Megalight, a photosensitive, energy efficient light designed for this

use. OK, OK, supposedly they are not as bright as "real"

masthead lights--who really knows, actually--but it's good enough.

Besides, it's better than not showing the light at all, which was my choice

much of the time.

Installing the new light was

a snap. It comes with its own bracket and wire lead, so all I had to

do was remove the existing lamp from the masthead, snip off the wires, and

install the new light in its own bracket, a much slicker arrangement than my

original setup anyway.

Click

here to see how I originally installed the old masthead light.

With

the new light bracket installed, I simply connected the wiring harness

to the existing wires in the mast, using heat-shrink connectors. Then,

as before, I wrapped the wire in black electrical tape to keep it neat and

less ugly, and secured the wire around the VHF antenna, as before. With

the new light bracket installed, I simply connected the wiring harness

to the existing wires in the mast, using heat-shrink connectors. Then,

as before, I wrapped the wire in black electrical tape to keep it neat and

less ugly, and secured the wire around the VHF antenna, as before.

|

|