|

Mast Support Beam Replacement

This page was last updated

on 26 November 2003.

Given

my worries about the mast support in general, and the repairs required

to the deck, it was only natural that I decided to inspect--and

remove--the existing mast support beam, which was original to the boat.

Removal involved removing several pieces of wooden trim, which were screwed in

place, and then the glued-on fabric over the beam.

It was obvious that there had been movement in the center portion,

especially in the forward add-on piece. There was a gap between

the beam and the bottom skin, and there was still room to hike the thing

upwards. The beam itself, however, was still in decent shape--the

same as before, so I wasn't sure initially how I was going to handle

is: reinforce, or build new. My initial thoughts were to

reinforce the beam with some metal plates, as this would avoid the need

to delve too deeply into the finished surfaces surrounding the

beam. On further inspection, though, it looked like the beam would

come out easily, if I could removed two small sections of tabbing and

cut the heads off a series of bolts passing through the forward

bulkhead. Given

my worries about the mast support in general, and the repairs required

to the deck, it was only natural that I decided to inspect--and

remove--the existing mast support beam, which was original to the boat.

Removal involved removing several pieces of wooden trim, which were screwed in

place, and then the glued-on fabric over the beam.

It was obvious that there had been movement in the center portion,

especially in the forward add-on piece. There was a gap between

the beam and the bottom skin, and there was still room to hike the thing

upwards. The beam itself, however, was still in decent shape--the

same as before, so I wasn't sure initially how I was going to handle

is: reinforce, or build new. My initial thoughts were to

reinforce the beam with some metal plates, as this would avoid the need

to delve too deeply into the finished surfaces surrounding the

beam. On further inspection, though, it looked like the beam would

come out easily, if I could removed two small sections of tabbing and

cut the heads off a series of bolts passing through the forward

bulkhead.

|

|

|

|

The next day, I attacked the beam

removal. It all started out well enough. First, I installed

a spiral bit in my Dremel tool, and easily cut through the tabbing on

each end of the beam. Then, with a cutting wheel in my 4-1/2"

grinder, I buzzed off the nuts securing the bolts running through the

beam; the heads were hidden in the vee berth behind the Formica bulkhead

covering, so I didn't want to try and re move them traditionally, as I

hoped to not disrupt the Formica. Cutting the nuts off released

the add-on section of the beam in the forward part of the passageway to

the vee berth, so I removed that section. Then I made

attempts to pry the beam out of position, which should have been

easy.

No luck--it barely

budged, though it moved enough that it seemed there was nothing serious

holding it in position. Thinking logically that the wood was

still gripping the4 or 5 bolts passing through the beam (even with the

nuts removed), I used a drill to ream the wood out around the bolts,

which should have released the beam. Still, I couldn't get the

beam to come out. I tried several approaches to no avail, and the

job rapidly became infuriating. There was no reason why the beam

shouldn't have come out, or so I thought. After all, I had managed

to pry it a short distance away from the bulkhead on each side, so I

figured there must not be anything really holding it. My mood was

made no better by an unfortunate lack of control with my pry bar at one

point; as nice as can be, the wild end caught the starboard head

porthole and shattered a hole in the glass in the blink of an eye.

I became somewhat more unhappy at this point, and might have spoken a

few harsh words. I can't remember; perhaps you should ask my

neighbors what they heard. No luck--it barely

budged, though it moved enough that it seemed there was nothing serious

holding it in position. Thinking logically that the wood was

still gripping the4 or 5 bolts passing through the beam (even with the

nuts removed), I used a drill to ream the wood out around the bolts,

which should have released the beam. Still, I couldn't get the

beam to come out. I tried several approaches to no avail, and the

job rapidly became infuriating. There was no reason why the beam

shouldn't have come out, or so I thought. After all, I had managed

to pry it a short distance away from the bulkhead on each side, so I

figured there must not be anything really holding it. My mood was

made no better by an unfortunate lack of control with my pry bar at one

point; as nice as can be, the wild end caught the starboard head

porthole and shattered a hole in the glass in the blink of an eye.

I became somewhat more unhappy at this point, and might have spoken a

few harsh words. I can't remember; perhaps you should ask my

neighbors what they heard.

|

|

After much struggle,

accompanied by a not-so-nice-something-is-being-ripped-apart sound, I

finally determined that there were two secret screws (driven from the

forward side of the bulkhead back into the beam, so they were invisible

behind the Formica) holding the beam in place. The ripping sound I

had heard was actually the plywood bulkhead being torn apart as I tried,

unbeknownst to me, to pull the screw the wrong way through the

material. I was less than pleased at this new development, but at

least now it was a cinch to cut the screws with my Sawz-All and release

the beam. It came out easily after that. What a stupid hour

I had spent. But the beam was out, never to return: I

planned to build a new, laminated beam to go in its place. After much struggle,

accompanied by a not-so-nice-something-is-being-ripped-apart sound, I

finally determined that there were two secret screws (driven from the

forward side of the bulkhead back into the beam, so they were invisible

behind the Formica) holding the beam in place. The ripping sound I

had heard was actually the plywood bulkhead being torn apart as I tried,

unbeknownst to me, to pull the screw the wrong way through the

material. I was less than pleased at this new development, but at

least now it was a cinch to cut the screws with my Sawz-All and release

the beam. It came out easily after that. What a stupid hour

I had spent. But the beam was out, never to return: I

planned to build a new, laminated beam to go in its place.

|

|

|

|

After cleaning up the

mess in the cabin--dust, splintered wood, and the like--and removing the

broken port, I felt much better, as if things had returned to some

semblance of control. Mass destruction of a finished boat is less

than my favorite thing. With the beam now on my bench, I inspected

it and found that it was in generally good condition, with only minor--and

expected--checks. Still, the sawn beam is inherently prone to some

flattening of the arch when under load, so I felt good about my decision

to build new. I put the beam aside for a week or so while I

concentrated on completing the deck-repair

portion of the mast step project. After cleaning up the

mess in the cabin--dust, splintered wood, and the like--and removing the

broken port, I felt much better, as if things had returned to some

semblance of control. Mass destruction of a finished boat is less

than my favorite thing. With the beam now on my bench, I inspected

it and found that it was in generally good condition, with only minor--and

expected--checks. Still, the sawn beam is inherently prone to some

flattening of the arch when under load, so I felt good about my decision

to build new. I put the beam aside for a week or so while I

concentrated on completing the deck-repair

portion of the mast step project.

|

|

|

|

Building a New Beam

After concentrating on the mast step

reinforcement and deck repairs for a number of days, as well as waiting

for delivery of some lumber with which to fabricate the new beam, I

eventually turned my attention to the issue of constructing a new

beam. I chose to cold mold the new beam out of epoxy-laminated

strips of white oak, which would form a very strong beam resistant to

the forces placed upon it by the mast compression.

The

white oak lumber I ordered came in the rough state, with a nominal 4/4

dimension. I received two boards, each about 9' in length and

between 7" and 9" wide. I thought I could get all the

material I needed out of the larger of the two boards, so I began with

that. The first step was to plane the board smooth on each side,

which reduced its overall thickness to about 3/4". Knowing

how much rough lumber I would be using in the future as I complete

projects on Glissando and also for the construction of the Triton

Daysailor, I decided to invest in a small thickness planer rather

than fight with other means of smoothing the boards. I purchased a

12" Delta planer and, in the days before beginning work on the mast

beam, I experimented with the tool to gain some knowledge of its use. The

white oak lumber I ordered came in the rough state, with a nominal 4/4

dimension. I received two boards, each about 9' in length and

between 7" and 9" wide. I thought I could get all the

material I needed out of the larger of the two boards, so I began with

that. The first step was to plane the board smooth on each side,

which reduced its overall thickness to about 3/4". Knowing

how much rough lumber I would be using in the future as I complete

projects on Glissando and also for the construction of the Triton

Daysailor, I decided to invest in a small thickness planer rather

than fight with other means of smoothing the boards. I purchased a

12" Delta planer and, in the days before beginning work on the mast

beam, I experimented with the tool to gain some knowledge of its use.

Planing

was uneventful. Given the hardness of the oak, and the

novelty of the planer to me, I was conservative in how much material I

removed with each pass, so it took a number of passes before the wood

was smooth, flat, and at the proper thickness. I was pleased with

the performance of the planer on the tough white oak. |

|

Next, I crosscut the board to make it easier to handle, and to reduce its

length to that which I wanted to use for the new beam. After

measuring the existing beam, and allowing plenty of extra, I cut the board

off at 6' in length. Conveniently, this left more than enough length

in the board to use the short cutoff as the stock for the additional

reinforcing section of the beam that extends forward into the vee berth

from the main beam.

With that done, I turned to

the next task: ripping the board into strips of the proper width and

thickness. The edges of the board were curved, so I set up a long

straightedge and trimmed one edge with a circular saw, being careful to

remove only the minimum amount of wood possible. With one straight

edge, I could begin ripping the board into strips of the proper width for

the new mast beam. The old beam was just about 2" wide, so I

decided to go just over 2" for the new one. At that width, I

managed to rip four strips out of the original board, with only a narrow

piece of waste left over.

|

|

Now I had to resaw each

strip to reduce the thickness of the boards that I would use for the

lamination. I had originally hoped to use boards of about 1/4"

in thickness, which would have given me 12 laminations in the 3"

height of the beam and all but eliminated any appreciable springback after

gluing. However, the original oak board was not thick enough to get

three 1/4" pieces from, and I didn't wish to waste so much material

in order to only get two boards. Instead, I decided to resaw each

strip in half, which gave me new boards of about 3/8" in thickness

with no material left over. I used the table saw to resaw the

boards, and ended up with 8 boards, giving me a total height of the

desired 3". Using a formula for roughly calculating springback,

I determined that with 8 laminations, I could be looking at nearly

1/4" of potential springback after the wood was glued. I would

have to take this into account when constructing the mold.

With the 8 main pieces

milled to the proper dimensions, I continued by milling the shorter

lengths into similarly-dimensioned pieces for later use as the beam

reinforcement as mentioned above.

|

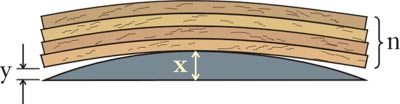

Computing

springback in a curved laminate

When a strip

of wood, a ply, is bent to a curve and released, it springs back to its

original shape. A stack of loose plies will do the same. When these plies

are glued together while clamped to a curve, they tend to stay curved, but

will straighten out or spring back a little. When building the mold or

form for the laminate its common to make the curve a little tighter to

compensate for the springback. The amount of springback depends on the

number of plies in the laminate, not in the ply material or the ply

thickness. A simple formula can help predict the amount of springback you

can expect:

y

= x/n2

y

= the amount of springback

x = the amount of deflection

n = the number of plies

Thus

with four plies, the springback (y) will be 1/16" if the amount of

deflection (x) is 1". By using plies half the thickness you double

the number of plies for a given thickness of laminate and reduce

springback four times-in this case to 1/64".

Tip

courtesy of West System website.

|

|

I decided to laminate the

beam on a horizontal mold, rather than a vertical one. Having read

others' experiences with laminating over a saddle-type vertical mold, I

thought it would be more convenient and easier to have the whole mold

built on a flat platform, with the strips oriented on edge. This

would help keep the edges of the strips aligned, would prevent side

slippage, and would prevent epoxy spillout from pouring into the clamps--a

common problem with the other method.

I began with a sheet of

particle board that I had lying around. I ripped it in half and

secured the two pieces together with screws and 2x4 bracing beneath across

the seam, giving me a flat platform of an appropriate width and

length. Having the 2x4s beneath had the added benefit of raising the

platform off the bench, which I thought might come in handy should I need

to clamp the beam in a downward direction during lamination. I laid

the old beam down on the platform and traced its profile directly on the

particle board. Because the old beam was slightly taller on its

aft-facing edge (since the top was beveled to approximate the angle of the

cabin trunk), I chose to trace it in that direction, which would give me

the tallest beam necessary and replicate the largest arc. I marked a

straight baseline and determined the beam centerline, and made the

appropriate marks. With the outline traced, I covered the whole platform

in some 6 mil clear plastic, which would protect it from epoxy and would

also prevent the new beam from sticking once it was glued up.

To

take the potential springback into consideration, I made a new mark at the

centerline of the beam arc, but 1/4" higher. Just beneath this

mark, I screwed a short piece of 2x4. Then, at each end of the beam

tracing, I screwed in another short piece of 2x4, but kept those edges at

the original marks. With the center of the new shape 1/4"

higher, the theory is that the ends will spring up enough when the

material is glued and cured, and will therefore ensure that the beam ends

up with approximately the correct shape and arc. To

take the potential springback into consideration, I made a new mark at the

centerline of the beam arc, but 1/4" higher. Just beneath this

mark, I screwed a short piece of 2x4. Then, at each end of the beam

tracing, I screwed in another short piece of 2x4, but kept those edges at

the original marks. With the center of the new shape 1/4"

higher, the theory is that the ends will spring up enough when the

material is glued and cured, and will therefore ensure that the beam ends

up with approximately the correct shape and arc.

To

ensure a fair curve and the proper placement of additional clamping

blocks, I bent one of the oak plies around the three main blocks (center

and two ends), and traced its arc on the plastic. Then, I installed

further blocking beneath this line, with blocks located every couple

inches. To complete the mold, I added small pieces of plastic

sheeting over the end of each 2x4 block to prevent the beam lamination

from sticking irrevocably to the mold. I added a final block on each

end well outside the actual end of the beam shape; the arc must continue

past the actual stopping point to ensure that the curve is fair and

smooth. To

ensure a fair curve and the proper placement of additional clamping

blocks, I bent one of the oak plies around the three main blocks (center

and two ends), and traced its arc on the plastic. Then, I installed

further blocking beneath this line, with blocks located every couple

inches. To complete the mold, I added small pieces of plastic

sheeting over the end of each 2x4 block to prevent the beam lamination

from sticking irrevocably to the mold. I added a final block on each

end well outside the actual end of the beam shape; the arc must continue

past the actual stopping point to ensure that the curve is fair and

smooth.

|

|

Not

wanting any unpleasant surprises while the wood strips were covered in

gooey epoxy, I decided to perform a dry run of the lamination to see if

any issues arose. I clamped all eight strips securely on the

centerline, and began pulling them in towards the mold on each side.

I found that it was helpful to place a squeeze clamp (such as a Quick

Grip) at the end location and pull the plies in from the end, clamping the

sections closer to the centerline as I went. I soon realized that I

would need some sort of hold-down clamping setup to keep the plies in

line, as they tended to slip in a vertical direction even with no epoxy in

place yet. To that end, I clamped a couple scraps of wood across the

plies and pulled them tightly down, which nicely aligned the plies.

This was the sort of issue I had hoped to uncover during the dry fit. Not

wanting any unpleasant surprises while the wood strips were covered in

gooey epoxy, I decided to perform a dry run of the lamination to see if

any issues arose. I clamped all eight strips securely on the

centerline, and began pulling them in towards the mold on each side.

I found that it was helpful to place a squeeze clamp (such as a Quick

Grip) at the end location and pull the plies in from the end, clamping the

sections closer to the centerline as I went. I soon realized that I

would need some sort of hold-down clamping setup to keep the plies in

line, as they tended to slip in a vertical direction even with no epoxy in

place yet. To that end, I clamped a couple scraps of wood across the

plies and pulled them tightly down, which nicely aligned the plies.

This was the sort of issue I had hoped to uncover during the dry fit.

Another problem that

surfaced was that, when placed under clamping pressure, one or two of the

2x4s split around the screw holes--a common problem with junk timber,

especially older ones that were dry. It was a snap to replace the

broken ones, but I was glad to have discovered the weakness before the

actual glueup.

|

|

Happy

that it looked like all was going to work fine, I unclamped the dry-fit

beam and made final preparations for the actual glue-up. I covered

one of my benches in spare plastic, so that I could keep the surface clean

while wetting out and spreading the epoxy on the wood plies, and laid out

my clamps and other equipment near the mold location on the other

free-standing bench. I gathered extra clamps and set them nearby,

just in case, and collected spare pieces of plastic and scrap wood, along

with my deadblow mallet, trying to prepare for any contingency.

While there is always more time than expected to work with the epoxy when

used in this sort of method, I wanted to take no chances. Happy

that it looked like all was going to work fine, I unclamped the dry-fit

beam and made final preparations for the actual glue-up. I covered

one of my benches in spare plastic, so that I could keep the surface clean

while wetting out and spreading the epoxy on the wood plies, and laid out

my clamps and other equipment near the mold location on the other

free-standing bench. I gathered extra clamps and set them nearby,

just in case, and collected spare pieces of plastic and scrap wood, along

with my deadblow mallet, trying to prepare for any contingency.

While there is always more time than expected to work with the epoxy when

used in this sort of method, I wanted to take no chances.

|

|

After

laying out the eight plies in the order I wanted them (I chose a smooth,

nice face for the ply that would end up forming the bottom--and most

visible--portion of the new beam), the first step was to wet out one side

of each ply with unthickened epoxy. The purpose of this was to

ensure that all areas of every bonding surface would be coated with epoxy,

but without creating excess waste from the inevitable squeeze out. I

spread the epoxy on the upturned side of each ply, ensuring that they were

evenly wet out. After

laying out the eight plies in the order I wanted them (I chose a smooth,

nice face for the ply that would end up forming the bottom--and most

visible--portion of the new beam), the first step was to wet out one side

of each ply with unthickened epoxy. The purpose of this was to

ensure that all areas of every bonding surface would be coated with epoxy,

but without creating excess waste from the inevitable squeeze out. I

spread the epoxy on the upturned side of each ply, ensuring that they were

evenly wet out.

|

|

With that step complete, I took one last look

around to ensure I was ready for the main lamination, and went ahead and

mixed up a batch of epoxy resin thickened to an adhesive texture with

cabosil. I left the mix quite loose to allow it to spread easily and

flow well once pressure was applied during clamping. The idea in

laminated glue-ups is to provide an even, consistent layer of adhesive

between each strip, without squeezing out all the glue and without

creating thick pockets of adhesive that are difficult to even out under

pressure. I thought I mixed more than enough, but of course halfway

through the process I ran out and had to mix up another batch.

Beginning with the lowest layer, I spread the adhesive on, then stacked

the next ply on top--with the resin-wetted side facing the just-applied

thickened epoxy--and then repeated the process till all eight boards were

stacked on the bench, oozing epoxy.

|

|

Then,

I picked up the stack and placed it on the mold, aligning the ends of the

boards and lining the centerline up with the marked line on the

mold. I installed one clamp in the center, fairly tightly, and then

placed one of my squeeze clamps at each end to begin pulling the plies

into the mold. I drew it in a bit, then installed more clamps from

the center outward towards the end, gradually pulling the whole mess is

towards the mold blocks. I didn't worry at this stage about

unevenness in the top edges of the boards; I'd take care of that later. Then,

I picked up the stack and placed it on the mold, aligning the ends of the

boards and lining the centerline up with the marked line on the

mold. I installed one clamp in the center, fairly tightly, and then

placed one of my squeeze clamps at each end to begin pulling the plies

into the mold. I drew it in a bit, then installed more clamps from

the center outward towards the end, gradually pulling the whole mess is

towards the mold blocks. I didn't worry at this stage about

unevenness in the top edges of the boards; I'd take care of that later.

|

|

Once

all the main clamps were on, I used my deadblow to roughly even out

the tops of the strips--wearing safety glasses in case the hammer blows

splattered epoxy spillout everywhere. Then, when I was satisfied

with the pressure on all the clamps, I installed a pair of hold-downs, one

at each end, which I had practiced with during the dry fit. Each was

made from a piece of scrap ash, which I rested on top of the laminated

plies with a piece of plastic to prevent epoxy adhesion, and I installed a

clamp on each end to pull the scraps down, which had the effect of evening

out the plies. Once

all the main clamps were on, I used my deadblow to roughly even out

the tops of the strips--wearing safety glasses in case the hammer blows

splattered epoxy spillout everywhere. Then, when I was satisfied

with the pressure on all the clamps, I installed a pair of hold-downs, one

at each end, which I had practiced with during the dry fit. Each was

made from a piece of scrap ash, which I rested on top of the laminated

plies with a piece of plastic to prevent epoxy adhesion, and I installed a

clamp on each end to pull the scraps down, which had the effect of evening

out the plies.

|

|

|

|

I

spent some time ensuring that all the clamps were properly situated, and

added a third flattening clamp setup on the centerline, where there was

some tendency for the beam to spring up. Then I used a plastic

squeeze to clean up as much of the squeezeout from the top of the beam and

around the edges as possible, to make sanding and surfacing easier later

(cured epoxy and cabosil makes for very difficult sanding). Then,

just to be sure, I laid the old beam on top of the clamps and compared the

curves. I had done this several times earlier in the process, of

course, but it never hurts to check again. The curves matched

closely, allowing for the additional 1/4" of height on the new beam

to account for springback. I

spent some time ensuring that all the clamps were properly situated, and

added a third flattening clamp setup on the centerline, where there was

some tendency for the beam to spring up. Then I used a plastic

squeeze to clean up as much of the squeezeout from the top of the beam and

around the edges as possible, to make sanding and surfacing easier later

(cured epoxy and cabosil makes for very difficult sanding). Then,

just to be sure, I laid the old beam on top of the clamps and compared the

curves. I had done this several times earlier in the process, of

course, but it never hurts to check again. The curves matched

closely, allowing for the additional 1/4" of height on the new beam

to account for springback.

|

|

|

|

|

|

I

left the beam to sit in the mold and clamps

for nearly 36 hours, to ensure that the epoxy would reach an advanced stage

of cure, before continuing. Then, I unclamped it and, with a small

amount of effort, broke it free from the plastic-covered mold. It

took some minor persuasion in one or two spots where the epoxy had oozed

out more heavily, but in moments it snapped free, leaving behind a nearly

clean mold ready for another use, which I shortly put to work: using

the same techniques described above, I laminated up the smaller forward

section of the beam, using the offcuts of the same material. I left

the new piece to cure in the mold for a day or two, and turned my

attention once more to the large beam. I

left the beam to sit in the mold and clamps

for nearly 36 hours, to ensure that the epoxy would reach an advanced stage

of cure, before continuing. Then, I unclamped it and, with a small

amount of effort, broke it free from the plastic-covered mold. It

took some minor persuasion in one or two spots where the epoxy had oozed

out more heavily, but in moments it snapped free, leaving behind a nearly

clean mold ready for another use, which I shortly put to work: using

the same techniques described above, I laminated up the smaller forward

section of the beam, using the offcuts of the same material. I left

the new piece to cure in the mold for a day or two, and turned my

attention once more to the large beam.

The surface of the beam

that had been facing upward was relatively free of epoxy, but there was

some slight unevenness in the plies. The other side, the one that

had been firmly pressed into the plastic, was covered with a thin, smooth,

even layer of epoxy spillout, with additional minor unevenness to match

the other side. The beam overall was straight, true, and free from

twists or other problems--not that I was worried, but it was still nice to

see a new project turn out as expected. Springback was minimal when

I unclamped the piece--perhaps 1/8", but certainly less than the

projected 1/4". I was very pleased with the result.

My next step was to remove

the thick globs of hardened epoxy from the edges, and then to sand the

beam smooth, particularly on the aft-facing side, which was to be

varnished and exposed in the cabin. The forward side would be

invisible, so all I had to do was smooth it to ensure it was flat and

even. To

clean up the beam, I briefly considered trying to run the whole thing

through the planer, but decided that it was prudent to at least try

sanding first, lest I ruin the beam, the planer knives, or both in the

process. To sand the beam, I used a belt sander with 60 grit paper,

running the sander perpendicularly across the plies to even out any

irregularities and to remove excess epoxy. Once the whole face was

smooth, I ran the sander with the grain to remove cross-grain marks caused

by the flattening process. Then, I used a DA sander to sand the top

and bottom edges of the arc, just enough to remove the epoxy oozeout and

handprints. The sanding wasn't particularly difficult at all, and

did a fine job cleaning up the beam. More final sanding will occur

later in the process before the beam is varnished and installed for good.

|

|

Next, I began the process of sizing and

fitting the beam. First, I laid the old beam on top, and marked the

ends on the new beam. Then, to double check how the old beam fit, I

took it up to the boat and put it in place, and noted that it didn't

extend all the way to the sides of the cabin. Therefore, I decided

to cut the new beam slightly longer, which would not only give me a fudge

factor for the final fitting, but also might allow me to run the beam all

the way to the edges. With my checking and double checking done, I

cut the new beam roughly to length on the chop saw. The clean cut

highlighted the even, thin  glue lines between the plies, indicating that

the clamping pressure appeared to have been even and appropriate. glue lines between the plies, indicating that

the clamping pressure appeared to have been even and appropriate.

With the beam cut to

length, I tried fitting it in place. Because of a slightly different

arc built into the new beam, I found I had to remove a small amount of

material from each of the two vertical support posts on the port side so

that the new beam could slide over the top. I cut these with a hand

saw, which was made overly difficult and time-consuming because of the

fine teeth on the one decent backsaw I had.

|

|

My first attempt at a dry

fit revealed that I had to cut the ends at a slight angle relative to the

face of the beam, to accommodate the fact that the cabin trunk narrows as

it runs forward. A compound miter box would have been nice, but

since I don't have one, I worked out a way to use my fixed miter box to

make the cuts at the appropriate angle (about 11.5 degrees). After a

few more trial fits and slight modifications to the ends and the top

surface of the beam (slight stock removal in a few areas necessary), the

beam slid tightly into place--just the fit I wanted. I still needed

some minor persuasion to get the beam snugly into its home, but it wasn't

so tight that it was being forced.

|

|

|

|

With

the beam fit in place, I marked the extent of the opening in the bulkhead

on the forward side of the beam, and prepared to cut the smaller laminated

sub-beam to fit. After measuring, cutting overly long on purpose,

and some additional trial fitting, I had the second beam section properly

sized. I discovered that, because of the forward-sloping top of the

coachroof, the small beam section protruded below the main beam by

1/4" or so--had I though it through, I could have simply eliminated 1

or 2 of the laminations during the build process. Now, however, I

needed a way to trim the bottom of the small beam down to

size. With

the beam fit in place, I marked the extent of the opening in the bulkhead

on the forward side of the beam, and prepared to cut the smaller laminated

sub-beam to fit. After measuring, cutting overly long on purpose,

and some additional trial fitting, I had the second beam section properly

sized. I discovered that, because of the forward-sloping top of the

coachroof, the small beam section protruded below the main beam by

1/4" or so--had I though it through, I could have simply eliminated 1

or 2 of the laminations during the build process. Now, however, I

needed a way to trim the bottom of the small beam down to

size.

At first, I thought I would

try to make the small beam flush with the main beam. Since I don't

have a bandsaw, my tool of choice was my portable jigsaw.

Unfortunately, the saw made a terrible cut because of blade wander through

the thick, dense material. While the visible cutline on top of the

beam seemed OK while I was making it, when I finished I realized that the

cut was completely unacceptable: wavy, uneven, and just awful.

I put the piece aside for the night while I thought about other courses of

action.

In the end, I decided to

use my belt sander to remove the material necessary, since none of the

saws I had were up to the task. Using the main beam as a guide, I

marked a smooth arc on each side of the small beam with a pencil, clamped

the beam upside down in a Workmate, and fired up the belt sander.

The coarsest sanding belt I had was 80 grit, and I went through three

belts as I removed nearly 1/4" of white oak. It only took about

10 minutes, and I was pleased with the end result. Since a flush fit

was impossible (after my botched initial cut), I chose to recess the

forward piece by about 1/4".

|

|

With that done, and a final

trial fit, the beams were complete. I removed both pieces and

performed some finish milling. I routed a 3/4" roundover in the

area where the beams span the passageway, and a 1/4" roundover on the

remaining edge of the main beam, and then sanded both sections smooth

through 220 grit. The beams cleaned up extremely well, and the

large-radius rounded edges just screamed out to be touched.

I applied

a coat of sealer varnish (50% varnish, 50% thinner) to the beams to

prevent any staining or discoloration before continuing with the final

fitting.

I

decided to emulate the original installation technique, which had

certainly seemed adequately strong and suitable for the task. The

original beams were bolted through the main bulkhead and to each other,

and featured no other means of attachment except for some lightweight

tabbing at the beam ends. The load from the mast is transferred

directly downwards through the beam arch and into the compression posts

secured to the bulkhead, with some load transfer also occurring through

the bolts and into the bulkhead.

I

ordered some 5/16" silicon bronze carriage bolts from Jamestown

(expensive!) in two lengths--one set for bolting the main beam to the

bulkhead (3-1/2"), and some longer ones for bolting the two sections

of beam together in the center (4-1/2"). I went with bronze for

strength, longevity, and, mostly, looks, since the bolts would be visible

in the final product.

With

the beams in place, I marked exactly where the forward section of beam

fell against the main beam, and then removed both sections one last

time. The marks were important because I needed to mock up the setup

on the bench so that I could drill holes for the bolts, and so that the

boltholes could be located in an aesthetically pleasing manner. With

the beams in place, I marked exactly where the forward section of beam

fell against the main beam, and then removed both sections one last

time. The marks were important because I needed to mock up the setup

on the bench so that I could drill holes for the bolts, and so that the

boltholes could be located in an aesthetically pleasing manner.

I

marked for three holes towards the center of the beam, evenly spaced

through the smaller forward beam section, and four additional holes--two

per side--for attaching the main beam to the bulkhead. Then, I

drilled all 7 holes with a 21/64" bit on my drill press.

With

the holes drilled, I lightly sanded the beams and applied the first of

several more coats of varnish before installing the beams in the boat.

I finished up with a coat of a floor polyurethane, with a satin sheen

finish, that looks simply awesome on oak.

|

|

|

|

When

the varnish was complete, I

installed the beam in the boat. To secure it, I used silicone bronze

carriage bolts through the main bulkhead, with the rounded heads facing

the (suitably) head, and the nuts and washers in the forward cabin.

I attached the sistered forward portion of the beam with three similar,

though longer, bolts. I decided that the bolts were more than

sufficient to secure the beam. Fortunately, the new beam fit closely

enough to the overhead, especially in the crucial center span beneath the

mast step, that no further reinforcement was needed. When

the varnish was complete, I

installed the beam in the boat. To secure it, I used silicone bronze

carriage bolts through the main bulkhead, with the rounded heads facing

the (suitably) head, and the nuts and washers in the forward cabin.

I attached the sistered forward portion of the beam with three similar,

though longer, bolts. I decided that the bolts were more than

sufficient to secure the beam. Fortunately, the new beam fit closely

enough to the overhead, especially in the crucial center span beneath the

mast step, that no further reinforcement was needed.

|

|

I

trimmed out the edges of the mast beam with narrow mahogany strips, many

of which I had used in the original setup. I also had to cut a few

new pieces of trim here and there to replace some of the old pieces that

didn't fit properly anymore. I

trimmed out the edges of the mast beam with narrow mahogany strips, many

of which I had used in the original setup. I also had to cut a few

new pieces of trim here and there to replace some of the old pieces that

didn't fit properly anymore.

The mast beam replacement

was complete!

|

|