|

Reinforcing the

Mast Step

This page was last updated

on 17 January 2004.

During the summer of 2003, I became

somewhat concerned about the condition of the mast beam and/or mast

step. During the initial restoration of the boat, I did not recore

the coachroof, nor did I replace the mast beam as is common. The

mast beam looked to be in good condition, and with so many other

projects to complete I did not see a reason to do the mast beam at that

time. There were no obvious signs of damage to the deck, and there

was no need to core the area at the time, as sounding and other standard

tests revealed no evidence of compromised core.

The factors leading to my

concern were twofold: first, I had had a leak through the nearby

wire chase for the mast wires, which I corrected early in the season

after I noticed it, but I was unsure how long it had been going

on. Second, the main upper shrouds' turnbuckles, were cranked up

nearly all the way, which was definitely more than they had been three

years earlier when the mast was stepped for the first time since the

restoration. Part of this was because the wire was an inch or so

longer than it should have been, as the turnbuckles were always cranked

up more than I would have wanted ideally, but I felt that it was worse

than it had been.  Also, I noticed

water pooling around the mast step during the season, and there was a

definite depression in the area. Also, I noticed

water pooling around the mast step during the season, and there was a

definite depression in the area.

With

the boat at home in the shop after the season ended, one of the first

things I did was remove the mast step from the deck to determine what,

if anything, was going on beneath. I also removed the wire chase

fitting, which exposed some rotted core (which was new since I installed

the fitting three years earlier--bummer).

I

sounded the deck beneath the mast step, which revealed evidence of

moisture saturation in the core beneath. So, if nothing else, it

looked like I was going to be faced with removing the core in that

immediate area and filling the area with solid fiberglass reinforcement |

|

A

few days later, I bit the bullet and cut a hole in the deck.

Taking a saw to a nice deck is always somewhat traumatic, though with my

previous experience recoring the boat several years ago it was less of

an issue for me--even though the boat now was nicely finished, when

before it was a near derelict. Perception and experience changes

all. However, there was no reason to mess around here: the

deck needed reinforcement, so I marked off an area about 12" wide

and 24" athwartships to remove the top skin (after measuring

the location of the mast step and taking photos of the whole area to

ensure proper placement later). Then, with my small circular saw

set to about 1/4" depth, I cut out the top skin. It took no

time at all, but cutting fiberglass in this manner creates copious

amounts of dust and debris. What a mess! A

few days later, I bit the bullet and cut a hole in the deck.

Taking a saw to a nice deck is always somewhat traumatic, though with my

previous experience recoring the boat several years ago it was less of

an issue for me--even though the boat now was nicely finished, when

before it was a near derelict. Perception and experience changes

all. However, there was no reason to mess around here: the

deck needed reinforcement, so I marked off an area about 12" wide

and 24" athwartships to remove the top skin (after measuring

the location of the mast step and taking photos of the whole area to

ensure proper placement later). Then, with my small circular saw

set to about 1/4" depth, I cut out the top skin. It took no

time at all, but cutting fiberglass in this manner creates copious

amounts of dust and debris. What a mess!

|

|

|

|

The

core was still fairly well adhered to the underside of the top skin, so

to make it easier to remove the fiberglass I made several more cuts

across and lengthwise. The smaller pieces were easier to get

started. I used a large chisel to pry off the top skins, then used

the same tool to remove all the core from the area. The core was

in better condition than I had expected, but was obviously badly

compressed in the area directly beneath the mast step, and there were

definitely signs of rot and water damage--though not even close to the

extent of my decks back in 1999 when I bought the boat and embarked on a

major recore. Once all the core was removed, I swept it up and

vacuumed the entire area to keep things clean; with the boat finished, I

didn't want to grind the abrasive fiberglass dust into any shiny painted

or varnished surfaces. The

core was still fairly well adhered to the underside of the top skin, so

to make it easier to remove the fiberglass I made several more cuts

across and lengthwise. The smaller pieces were easier to get

started. I used a large chisel to pry off the top skins, then used

the same tool to remove all the core from the area. The core was

in better condition than I had expected, but was obviously badly

compressed in the area directly beneath the mast step, and there were

definitely signs of rot and water damage--though not even close to the

extent of my decks back in 1999 when I bought the boat and embarked on a

major recore. Once all the core was removed, I swept it up and

vacuumed the entire area to keep things clean; with the boat finished, I

didn't want to grind the abrasive fiberglass dust into any shiny painted

or varnished surfaces.

|

|

|

|

With

the core removed, I could see that the inner skin was cracked on each

side of the mast beam, where the deck had flexed around the more solid

beam over the years. I was happy to see that the core all the way

around my cutout was clean and dry, though. With

the core removed, I could see that the inner skin was cracked on each

side of the mast beam, where the deck had flexed around the more solid

beam over the years. I was happy to see that the core all the way

around my cutout was clean and dry, though.

Before

continuing with the fiberglass repair, I moved inside the boat to remove

the existing mast beam.

Click

here to read that portion of the job now.

Or, just keep reading, and you'll find another link to the mast beam at

the bottom of this page. |

|

My next

step was to laminate solid fiberglass in the area on deck where I

had removed the core beneath the mast step. First, though, I

sanded the inner skin in the uncored area to remove old resin and core

bits, and then, after cleaning the area thoroughly, mixed a small batch

of thickened epoxy and applied it to the edges of the opening, to seal

the surrounding core and to fill the small voids that had been created

when I removed the inner portion. Then, I began the laminating

process. Earlier, I had cut a number of pieces of fiberglass cloth

to the correct size for the opening. Because I had a large supply

of 10 oz. cloth on hand, and I was anxious to get the project completed,

I used the materials on hand. Heavier material would have filled

the area with fewer layers, of course, but my local supplier didn't have

any of the biaxial cloth I wanted, so I pressed on with the lighter

material.

Because

I was unsure how hot the resin I was using would cure (MAS low-viscosity

resin with medium hardener), I began with around 4 layers of

cloth. To make my life easier, I wet the material out on a piece

of cardboard on my bench, then carried the whole cardboard up to the

boat, where I transferred the glass to the opening and rolled it out. Because

I was unsure how hot the resin I was using would cure (MAS low-viscosity

resin with medium hardener), I began with around 4 layers of

cloth. To make my life easier, I wet the material out on a piece

of cardboard on my bench, then carried the whole cardboard up to the

boat, where I transferred the glass to the opening and rolled it out.

|

|

Over

the next several days, I repeated this process twice per day--in the

morning and late in the afternoon, which allowed the previous layers to

cure sufficiently while retaining the green stage that allowed the new

layers to chemically bond. Since there had been no signs of heat

from the 4 layers I used the first time, I increased the number as I

went, sometimes installing up to 8 layers at once. Any thicker

than that and it becomes hard to roll out the air, so I left it at

that. The cloth is so thin that 8 layers doesn't add up to that

much, thicknesswise. Over

the next several days, I repeated this process twice per day--in the

morning and late in the afternoon, which allowed the previous layers to

cure sufficiently while retaining the green stage that allowed the new

layers to chemically bond. Since there had been no signs of heat

from the 4 layers I used the first time, I increased the number as I

went, sometimes installing up to 8 layers at once. Any thicker

than that and it becomes hard to roll out the air, so I left it at

that. The cloth is so thin that 8 layers doesn't add up to that

much, thicknesswise.

|

|

Finally,

after several days of this, the material was built up thick enough to

approach the surface of the deck. I lost count of how many layers

it took to fill the 1/2" thick void. To avoid building up

fiberglass thicker than the surrounding deck surface, I erred on the

side of caution and left it a bit low, allowing the final layers to cure

before sanding off the edges and determining exactly how much more

material, or fairing compound, was to be necessary. Finally,

after several days of this, the material was built up thick enough to

approach the surface of the deck. I lost count of how many layers

it took to fill the 1/2" thick void. To avoid building up

fiberglass thicker than the surrounding deck surface, I erred on the

side of caution and left it a bit low, allowing the final layers to cure

before sanding off the edges and determining exactly how much more

material, or fairing compound, was to be necessary.

|

|

When the material was cured, I determined that the glass was built up

close enough (within 1/8") to the existing deck level--therefore,

no additional fiberglass was to be needed to fill the void, as I could

make up the small difference with structural fairing compound.

First, though, I sanded the rough edges of the patch, grinding off any

material that had spilled up over the edge during lamination.

Then, with the patch cleaned, I troweled in a coat of epoxy fairing

compound (low density filler and cabosil). To form a crown that

would match closely the surrounding, existing coachroof, I cut a

straight board to a bit wider than the patch, and used it as a screed to

smooth the putty and ensure that it was at the same level as the

surrounding deck, and at the same curvature.

|

|

Later,

after the latest coat kicked, I washed the epoxy with water, sanded off

any high or rough spots, and troweled in a smooth coat to fill the waves

and voids caused by the screed. This made the patch smooth and

level with the surrounding deck, and when it cured the area was ready

for the final layers of fiberglass reinforcement, which would strengthen

and tie the area in with the surrounding deck. Later,

after the latest coat kicked, I washed the epoxy with water, sanded off

any high or rough spots, and troweled in a smooth coat to fill the waves

and voids caused by the screed. This made the patch smooth and

level with the surrounding deck, and when it cured the area was ready

for the final layers of fiberglass reinforcement, which would strengthen

and tie the area in with the surrounding deck.

|

|

The

next morning, I washed and sanded the patch, and ground the deck a few

inches on each side of the patch to prepare for laying in the final

layers of material. I used 17 oz. biaxial tape to

glass the area, with two layers in the area directly under the step,

laid up in epoxy resin. I left the patch to cure fully before

continuing. The

next morning, I washed and sanded the patch, and ground the deck a few

inches on each side of the patch to prepare for laying in the final

layers of material. I used 17 oz. biaxial tape to

glass the area, with two layers in the area directly under the step,

laid up in epoxy resin. I left the patch to cure fully before

continuing.

|

|

|

|

With

the new fiberglass fully cured, I prepared it for the final fairing

steps by first washing it with water (not being sure if System Three resin

blushes appreciably or not and deciding to play it safe) and then sanding

it to eliminate high and rough spots, and to widen the sanded area of the

surrounding deck a bit so that the fairing compound could fair naturally

and smoothly into those areas. The new patch sits slightly

higher than the surrounding area, which is just what I wanted. I

intended to create a sort of "power bulge" in the deck around

the mast step, which bulge would be neatly faired into the coachroof and

thus barely noticeable. I also removed the protective plastic that

had been covering the surrounding deck, since with the messy fiberglassing

complete it was no longer necessary and was becoming a hindrance. With

the new fiberglass fully cured, I prepared it for the final fairing

steps by first washing it with water (not being sure if System Three resin

blushes appreciably or not and deciding to play it safe) and then sanding

it to eliminate high and rough spots, and to widen the sanded area of the

surrounding deck a bit so that the fairing compound could fair naturally

and smoothly into those areas. The new patch sits slightly

higher than the surrounding area, which is just what I wanted. I

intended to create a sort of "power bulge" in the deck around

the mast step, which bulge would be neatly faired into the coachroof and

thus barely noticeable. I also removed the protective plastic that

had been covering the surrounding deck, since with the messy fiberglassing

complete it was no longer necessary and was becoming a hindrance.

|

|

I

mixed up way too much (as usual) of a thick epoxy fairing compound using

low-density filler and cabosil, and troweled it over the edges of the

patch and through the middle, leaving just enough in place to fill the

weave of the cloth and to fair the edges down to the deck around. I

left it to cure overnight before continuing. I

mixed up way too much (as usual) of a thick epoxy fairing compound using

low-density filler and cabosil, and troweled it over the edges of the

patch and through the middle, leaving just enough in place to fill the

weave of the cloth and to fair the edges down to the deck around. I

left it to cure overnight before continuing.

|

|

I hand sanded the hardened

fairing compound the next morning, as it was smooth enough that I saw no

need to get out a machine. It was also easier to maintain the

pleasing curve and contours of the patch with hand sandpaper on a rubber

sanding block.

After

cleaning off the dust, I prepared to apply what I hoped would be the final

coat of fairing compound. I used a new product for me: System

Three Quick-Fair putty, a two-part epoxy material that already contained

thickening agents and therefore only required mixing the two parts in the

proper ratio. The material was extremely smooth and creamy in

texture, unlike the coarser texture of epoxy putties made with the

traditional fillers. It's designed to cure to a sandable stage in

3-4 hours, unlike the 24 or so hours requires for epoxy. After

cleaning off the dust, I prepared to apply what I hoped would be the final

coat of fairing compound. I used a new product for me: System

Three Quick-Fair putty, a two-part epoxy material that already contained

thickening agents and therefore only required mixing the two parts in the

proper ratio. The material was extremely smooth and creamy in

texture, unlike the coarser texture of epoxy putties made with the

traditional fillers. It's designed to cure to a sandable stage in

3-4 hours, unlike the 24 or so hours requires for epoxy.

|

|

I

applied the Quick-Fair using standard methodology, and was pleased with

the texture. After curing overnight, the material was hard and

sanded very easily and smoothly, leaving an excellent surface.

However, there were few pinholes in some of the exposed cloth (exposed

after the putty was sanded), so I mixed a small batch of the Quick-Fair

and applied it one final time, sticking only to those areas with pinholes

or other minor surface interruptions. I

applied the Quick-Fair using standard methodology, and was pleased with

the texture. After curing overnight, the material was hard and

sanded very easily and smoothly, leaving an excellent surface.

However, there were few pinholes in some of the exposed cloth (exposed

after the putty was sanded), so I mixed a small batch of the Quick-Fair

and applied it one final time, sticking only to those areas with pinholes

or other minor surface interruptions.

|

|

|

To complete the patch, I coated the fairing material with unmodified epoxy

resin, using a foam roller, and, after the material kicked, I sanded it

one final time. Then, I applied a coat of white primer as a final

preparatory step before the nonskid paint application.

|

|

|

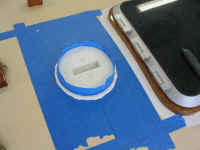

Later,

after repainting the nonskid and taking care of myriad other projects, I reinstalled the mast step in a heavy bed of 3M 101

polysulfide. As before, the step is simply screwed through the deck into the forward portion of the mast beam.

After drilling pilotholes and my usual countersink at the top, I filled each screwhole with 101, pressing the tip of the

caulking gun into the hole, and heavily caulked the entire base area of the step, the screwholes through eh step, and then,

after installing the screws, filled the remaining countersinks at the top (weather) side of the step with more

101. While the deck is now solid fiberglass in this area, I certainly wished to avoid any possibility of water

ingress into the wooden mast beam. When the caulk had cured overnight, I cut away the excess. Later,

after repainting the nonskid and taking care of myriad other projects, I reinstalled the mast step in a heavy bed of 3M 101

polysulfide. As before, the step is simply screwed through the deck into the forward portion of the mast beam.

After drilling pilotholes and my usual countersink at the top, I filled each screwhole with 101, pressing the tip of the

caulking gun into the hole, and heavily caulked the entire base area of the step, the screwholes through eh step, and then,

after installing the screws, filled the remaining countersinks at the top (weather) side of the step with more

101. While the deck is now solid fiberglass in this area, I certainly wished to avoid any possibility of water

ingress into the wooden mast beam. When the caulk had cured overnight, I cut away the excess.

Along with the deck repairs, I also built a new laminated mast beam

to support the area from beneath.

Please

click here to continue with the mast beam.

|

|